If you want the best electrical insulation and performance at work, you should look at ceramic coating insulated bearing options. Electrical insulation is very important. It helps protect bearings from damage. It also helps stop machines from breaking down. In many industries, insulation problems cause up to 18.5% of all bearing issues. Ceramic bearings and insulated bearings use special coating methods. These coatings stop stray currents that can cause early failures. You will see both ceramic coating insulated bearing and alumina coated insulated bearings in motors and heavy machines. Picking the right coating helps bearings last longer. It also makes machines work better.

Key Takeaways

Insulated bearings keep machines safe by blocking electric currents that can hurt them and make them break early. Ceramic coatings give better protection from electricity and heat than alumina coatings. This makes them good for machines that run fast and get hot. Alumina coated bearings also protect well from electricity and wearing out. They work well in motors and big machines. You need to pick the right bearing for your machine’s weight, speed, heat, and where it is used. This helps the machine last longer and work better. Cleaning and oiling insulated bearings often helps them last longer and saves money on repairs.

Insulated Bearings Overview

Purpose and Benefits

Machines need protection from electrical damage. Insulated bearings help with this job. If electric currents go through a bearing, they can make small holes. They can also cause false brinelling. This kind of damage makes bearings fail early. Insulated bearings have a special coating. This coating stops the currents from touching the rolling parts and raceways. Bearings last longer and machines work better.

Insulated bearings help save money. They lower maintenance costs. They also help stop machine downtime. You do not need extra insulation parts. This keeps your equipment design simple. Many insulated bearings, like ceramic or alumina coated ones, meet ISO standards. You can use them instead of regular bearings. You do not have to change your machine design.

Here are some main benefits of insulated bearings:

- Stop damage from electric currents

- Help oil last longer

- Prevent early failure in motors and generators

- Lower repair costs and stop production loss

- Keep machines running and save on maintenance

| Benefit | Explanation |

|---|---|

| Protection Against Electrical Damage | The coating blocks electrical erosion and pitting. |

| Enhanced Reliability | Strong design reduces downtime and maintenance. |

| Long Service Life | Durable coating extends how long your bearing lasts. |

| Versatility | You can use these bearings in many high-speed and heavy-load applications. |

| Cost-Effectiveness | Better performance means you save money over time. |

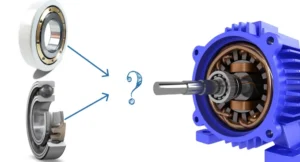

Types in Industry

There are different types of insulated bearings in big factories. Each type uses a special coating or material. These stop electric currents from causing harm. Motors in factories, mines, and power plants use these bearings. Variable frequency drives in these places make high-frequency currents. Insulated bearings, like outer-ring and inner-ring insulated types, help block these currents. They keep your machines safe.

Some common types are:

- Coated insulated bearings: These have a special coating on the rings or rolling parts. The coating sticks well and does not let water in.

- Ceramic insulated bearings: The rolling elements (balls or rollers) of this type of bearing have been replaced with ceramic rolling elements made of insulating materials.

You can pick the best bearing and coating for your machine. This helps your equipment work better and last longer.

Ceramic Coating Insulated Bearing

Construction

A ceramic coating insulated bearing is made with special materials. These materials are picked because they have helpful features. Some examples are silicon nitride, zirconium oxide, and aluminum oxide. First, the right material is chosen and turned into powder. The powder is shaped and heated to make it strong. Machines then cut and shape the hard ceramic pieces. After cleaning and checking, the bearing is put together. Last, a ceramic layer is sprayed on the outside. This layer keeps out electricity and protects the bearing from tough places.

| Material | Key Properties | Thermal Conductivity (W/m.K) | Max Temperature (°C) | Typical Applications |

|---|---|---|---|---|

| Silicon Nitride | Lightweight, high rigidity | 40-60 | 1900 | Aerospace, semiconductor equipment |

| Zirconium Oxide | High strength, toughness | 10-20 | 2200 | Chemical, medical applications |

| Aluminium Oxide | High melting point, high stability | 18-35 | 2000 | Capacitors, resistors |

You can look at the table to compare these materials. The chart shows how well each one handles heat and high temperatures.

Ceramic Insulation Coatings

Ceramic insulation coatings help keep your bearing safe. Most use oxide ceramics like alumina, spinel, or mullite. These coatings are sprayed on the bearing rings. The layer is thick and strong, usually between 50 and 200 microns. Plasma spraying melts the ceramic powder and puts it on the surface. This makes a tough coating that blocks up to 1000 volts. Thicker coatings give better insulation. The coating also stops rust and works well in wet or rough places.

Key Properties

Ceramic coating insulated bearings have many good points. The ceramic layer stops electricity from hurting your machines. These bearings are very hard and do not wear out fast. They are lighter than steel and do not rust. They can handle high heat. But ceramic can break if dropped, so you must be careful. The sprayed coating keeps working even when things get tough. You get a bearing that is strong, stable, and safe from electricity.

Tip: Using ceramic coating insulated bearings helps your machines last longer and need less fixing.

Applications

Ceramic coating insulated bearings are used in many fields. They are good for electric motors, planes, cars, and energy jobs. These bearings protect parts like turbine blades and gears from heat. In fuel cells and solar cells, they stop rust and block electricity. You will see that machines last longer and run smoother. The coatings help bearings work in fast, hot, and heavy jobs. This makes them a great pick for hard industrial work.

Alumina Coated Bearings

Construction

Alumina coated bearings get a special layer on the outside. Makers use heat to spray alumina powder onto the bearing rings. The hot powder sticks to the metal and forms a hard layer. This layer blocks electricity and stops the bearing from wearing out fast. After spraying, the surface is polished to make it smooth. This helps the bearing work well in tough places and last longer.

Properties

Alumina coated bearings are strong and keep out electricity. The alumina layer helps the bearing stay stable in heat. It also protects the bearing from electric currents. You can see the main features in the table below:

| Property | Typical Value/Range |

|---|---|

| Volume Resistivity (20℃) | ~10^14 Ω·cm |

| Dielectric Strength | 10–16 KV/mm |

| Dielectric Constant (1 MHz) | 9–9.9 |

| Bending Strength (20℃) | 300–600 MPa |

| Compressive Strength (20℃) | 2000–3500 MPa |

| Young’s Modulus (20℃) | 270–400 GPa |

| Mohs Hardness (20℃) | 8.0–9.5 |

| Vickers Hardness (HV1) | 1600–1800 kg/mm² |

Note: Alumina coated bearings do not get damaged by chemicals. They stay strong even when it gets very hot. The sprayed coating helps the bearing handle quick changes in heat and sudden shocks.

These bearings can take heavy loads and lots of heat. They also keep out electricity. The alumina coating helps the bearing last longer and work better in hard jobs.

Applications

Alumina coated bearings are used in many factories. They work in engines, motors, and machines that get very hot or have lots of force. Some common uses are:

- Internal combustion engine bearings

- Precision shafts and axles in places with lots of wear

- Mechanical seals and parts that rub together

- High-performance cars and factory machines

The sprayed coating helps the bearing fight wear and not break down. This means the bearing lasts longer and you do not have to fix it as much. The alumina layer helps the bearing work in hot and rough places. If you need a strong insulated bearing, alumina coated bearings are a good pick.

Comparison

Electrical Insulation

Ceramic coating insulated bearings and alumina coated bearings are different. Ceramic coatings, like mullite, give better electrical insulation than alumina. Mullite coatings block more electricity. They have higher impedance and lower relative permittivity. This means less current gets through. Machines are safer from breakdowns. Alumina coatings can break down more when there is a lot of current.

| Coating System | Relative Permittivity (εr) | Electrical Breakdown Behavior |

|---|---|---|

| Alumina (Reference) | ~9.0 | More breakdowns at higher bearing currents (≥ 0.6 A) |

| Mullite M2–SV2 | 4.9 ± 0.38 | Fewer breakdowns, better insulation than alumina |

| Mullite M1–SV2 | 5.0 ± 0.22 | Similar improved insulation as M2–SV2 |

| Mullite M1–EV2 | 3.8 ± 0.22 | Best performance, lowest breakdown currents, highest impedance |

Ceramic coatings, especially mullite, work better in wet places. They keep their insulation even when it is humid. If you need strong protection for electric motors, ceramic coatings are the best choice.

Mechanical Performance

Both ceramic coating insulated bearings and alumina coated bearings help machines work better. Ceramic coatings make bearings harder and less likely to wear out. They also lower friction, so machines use less energy. Bearings need less oil. Ceramic coatings stop rust and help bearings last longer.

| Feature | Ceramic Coating (e.g., Mullite, Alumina-based) | Alumina Coated Bearing |

|---|---|---|

| Hardness | Very high (3-5 times steel) | High |

| Brittleness | Higher, less flexible | High |

| Wear Resistance | Excellent | Excellent |

| Load Capacity | Limited by brittleness | Limited by brittleness |

| Friction Coefficient | Lower | Lower |

| Corrosion Resistance | Superior | Superior |

| Weight | Lighter | Lighter |

Alumina coatings have a special crystal structure. This makes them hard and good at fighting wear. Both coatings help in places with lots of rubbing or rust. But ceramic coatings can break if hit hard. These bearings are best where wear resistance is more important than carrying heavy loads.

Speed and Heat Resistance

Ceramic and alumina coated insulated bearings work well at high speeds and high heat. Ceramic coatings, including alumina ones, stay strong at very high temperatures. They can work up to 1800°C and even higher in a vacuum. This means bearings do not lose shape or stop working when hot or fast.

| Property | Value Range |

|---|---|

| Maximum Use Temperature | 1750 – 1800 °C |

| Operational Stability | Up to 1650 °C (atmosphere) |

| Operational Stability | Up to 2000 °C (vacuum) |

| Mechanical Strength | 50% tensile strength at 1000 °C |

- Ceramic insulated bearings, even with alumina coatings, are very hard and smooth.

- They last longer and need less fixing.

- They do not break down from heat, so they work well in fast machines.

- Ceramic coatings also stop electrical and rust damage.

You can use both types for jobs that need heat and speed protection.

Durability

You want bearings that last a long time. Ceramic coating insulated bearings last much longer than alumina coated ones. In tests, ceramic bearings with glass-alumina layers lasted up to 400,000 cycles under heavy load. Alumina coated bearings lasted only about 12 cycles at the same load. Both types fight wear and rust, but ceramic coatings stop cracks better.

| Test Aspect | Graded Glass-Alumina (Ceramic) | Homogeneous Alumina (Alumina Coated) |

|---|---|---|

| Mean fatigue life at ~710 N load | ~400,000 cycles | ~12 cycles |

| Surface wear after 1 million cycles at 200 N | ~7 µm depth, no cracks | ~9 µm depth, no cracks |

| Fracture resistance | Improved | Baseline |

| Load-bearing capacity | Higher | Lower |

Ceramic coated bearings also block electrical damage, which often breaks motors. This means you fix machines less and save money. You can get 4 to 8 times longer life than regular bearings. You still need to check and grease them, but not as often.

Cost

Both ceramic coating insulated bearings and alumina coated bearings help save money over time. They stop damage from electricity and heat, so you do not need to replace them as much. Hybrid ceramic bearings use silicon nitride parts. These cut friction by up to 30% and make grease last twice as long. This means machines run better and cost less to use.

- Alumina coated bearings use a sprayed aluminum oxide layer. This stops rust and electrical damage, so you spend less on repairs.

- Both types lower the number of fixes and machine stops, so you save on work and parts.

- Ceramic bearings cost more at first, but last longer and need less fixing. They are a good choice for fast, hot jobs.

Tip: Using insulated bearings with the right coating can stop failures from stray currents and heat. This gives you the best value for your money.

Recommendations

Selection Criteria

When you pick between ceramic and alumina coated insulated bearings, you must match the bearing to your machine and where it works. First, look at how big your machine is and how much weight it carries. Small machines use small bearings. Big machines need stronger ones. Think about how you will keep the bearing moving smoothly. Dry-run bearings are good for clean places. Most factories use grease or oil. If your machine gets very hot or works in a vacuum, solid lubricants are better.

Check how much weight the bearing can hold and how fast it can spin. Full ceramic bearings work well with medium weights and high speeds. Hybrid ceramic bearings are good if you want to save money and still need strength for bigger jobs. Always check the precision grade, like ABEC or ISO, to make sure the bearing fits your needs. You can also get special coatings, seals, or designs to help the bearing last longer and stop damage.

Before you choose a bearing, think about how your machine works. Look at the temperature, chemicals, weight, speed, and where the machine is used. Alumina ceramics can handle heat up to 1700°C, so they are good for hot jobs. Silicon nitride is extra hard and tough for heavy machines that wear out fast. If your machine faces acids or alkalis, zirconia helps stop rust. For electrical insulation, aluminum nitride is good because it blocks electricity and handles heat well.

Tip: Always keep your bearings clean and check them often. If you take care of your bearings, they last longer and do not break as much.

Mistakes can happen if you do not watch the details. If dust or dirt gets into ceramic bearings, they can break early. Ceramic bearings can also crack if they get hot or cold too fast or get hit hard. Pick the right coating and handle the bearings gently.

Best Use Cases

You should pick the right bearing for your job. The table below shows which bearing works best for different jobs:

| Operating Condition / Scenario | Best Bearing Type & Features | Application Examples |

|---|---|---|

| Extremely High Temperature (up to 800°C) | Full ceramic bearings with silicon nitride, no cage, special coating | Baking furnaces, high-heat industrial equipment |

| Vacuum and Clean Environments | Hybrid ceramic bearings, stainless steel rings, fluoropolymer lubrication, insulating coating | Semiconductor tools, inspection robots, LCD equipment |

| High-Speed or High-Voltage Applications | Hybrid ceramic bearings, high carbon steel rings, silicon nitride balls, oil/grease coating | High-speed motors, generators, some electric drives |

| Electric Motor Shaft Current Interruption | Alumina coated insulated bearings, thick aluminum oxide coating, high impedance | Electric motors, generators, standard bearing designs |

| Chemical or Corrosive Environments | Bearings with zirconia or special coating for corrosion resistance | Chemical plants, food processing, lab equipment |

Ceramic bearings with a special coating are best for very hot places, clean rooms, or places that need to go fast. They are good at handling heat and blocking electricity. Alumina coated bearings are best when you need to stop electric currents, like in electric motors. They are the same size as regular bearings and block electricity well.

If you want to pick the right bearing, start by writing down what your machine needs. Think about heat, speed, weight, and what kind of coating you want. You can always ask TFL Bearings for help. We can help you choose the best insulated bearing for your job. Our team will help you from picking to putting in your bearing.

You have many options when choosing insulated bearings. Alumina coated bearings give you strong electrical insulation and work well in motors. Ceramic bearings help your machines run fast and stay cool. You should always match the bearing to your machine’s needs.

- Think about load, speed, temperature, and environment.

- Pick the right type for longer life and better performance.

For expert help, reach out to us at TFL Bearings. We can guide you to the best solution for your industry.

FAQ

What is the main difference between ceramic and alumina coated bearings?

Ceramic coatings use things like mullite or silicon nitride. Alumina coated bearings use aluminum oxide. Ceramic coatings block electricity better than alumina ones. Alumina coatings are good for most electric motors.

Can you use insulated bearings in wet or humid environments?

Yes, you can use both types in wet places. Ceramic coatings, like mullite, still insulate well when it is humid. Both types protect against rust and electrical problems.

How do you know which insulated bearing to choose?

Check your machine’s speed, weight, and how hot it gets. Ceramic coatings are best for fast or hot machines. Alumina coated bearings are good for regular motors and heavy machines.

Do insulated bearings need special maintenance?

You do not need special care for these bearings. Keep them clean and look at them often. Use the right grease or oil. This helps them last longer and work better.