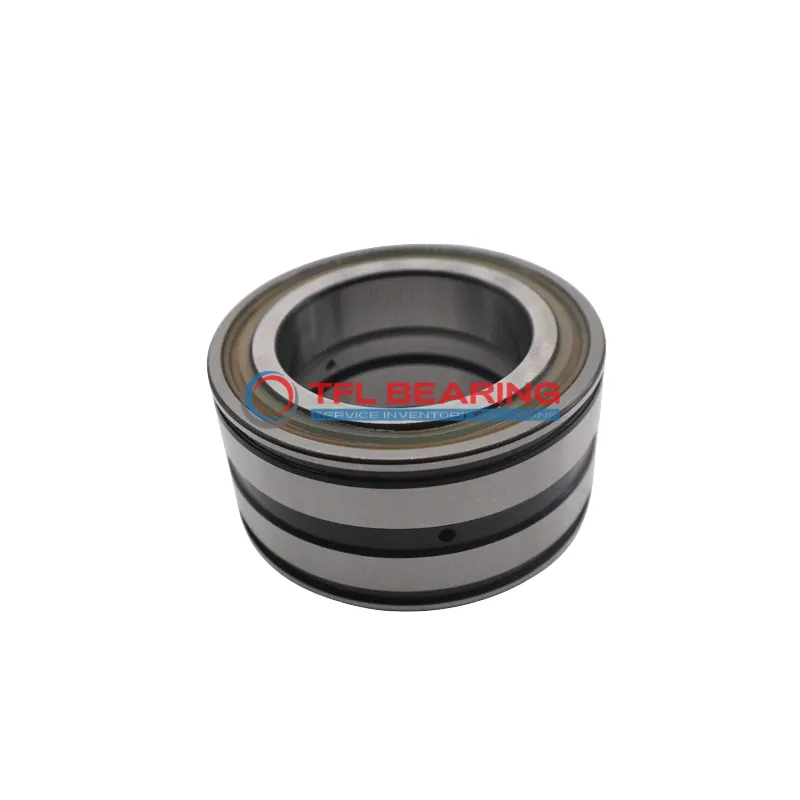

The 319440 B-2LS is a double-row cylindrical roller bearing with a 200mm bore and 270mm outer diameter, crafted from robust chrome steel. It supports combined loads up to 141075 lbf and works well in temperatures from -30°C to 110°C.

Its full-complement design (no cage) maximises load capacity, while the sealed construction keeps contaminants out. The bearing is pre-lubricated for grease or oil, making maintenance straightforward.

This model is interchangeable with SKF bearings, offering a reliable replacement option. Ideal for heavy machinery or industrial equipment where high radial loads are common.

Weighing 13.1kg, it’s built for durability in demanding environments. Compliant with RoHS and REACH standards for safe use.

"*" indicates required fields

Performance Features of 319440 B-2LS Bearing

319440 B-2LS Bearing is built with double-row full complement rollers, offering high load capacity and stability.

Its chrome steel construction ensures durability and resistance to wear in demanding conditions.

The sealed design protects against contaminants, making it suitable for harsh environments.

With a dynamic radial load capacity of 141075 lbf, it handles heavy-duty applications with ease.

How Does 319440 B-2LS Bearing Resist Wear?

319440 B-2LS Bearing uses 52100 chrome steel for both rings and rollers, enhancing its wear resistance.

The full complement roller design maximises load distribution, reducing stress on individual components.

Sealed against dust and moisture, it maintains performance in challenging conditions.

Its static radial load capacity of 308250 lbf ensures reliability under heavy loads.

Engineered for Precision: 319440 B-2LS Bearing

319440 B-2LS Bearing features precise tolerances, with bore diameter tolerance of -0.03mm to 0.

The double-row design provides excellent radial and axial load support in compact spaces.

Grease or oil lubrication options allow flexibility in maintenance.

Operating between -30° to 110°C, it performs consistently across a wide temperature range.

Steel vs Ceramic Bearings: Strengths of 319440 B-2LS Bearing

319440 B-2LS Bearing’s 52100 chrome steel construction offers a balance of strength and affordability.

The full complement roller arrangement increases load capacity compared to caged designs.

Sealed for protection, it requires less frequent maintenance in dirty or wet environments.

With a weight of 13.1 kg, it provides robust performance without excessive bulk.

Industrial Uses of 319440 B-2LS Bearing

319440 B-2LS Bearing is commonly used in heavy machinery like industrial gearboxes and large conveyor systems, where its double-row design handles high radial loads efficiently. The full complement of rollers ensures maximum load capacity without a cage, making it ideal for slow-speed, high-load applications.

Where Is 319440 B-2LS Bearing Used?

You’ll often find 319440 B-2LS Bearing in mining equipment and construction machinery, where its sealed design protects against dust and debris. The chrome steel construction also provides excellent durability in harsh environments.

Built for Heavy-Duty Use: 319440 B-2LS Bearing

319440 B-2LS Bearing excels in applications like rolling mills and presses, where combined loads are common. Its grease or oil lubrication options allow for flexibility in maintenance, depending on operational needs.

Automotive vs Aerospace: Applications of 319440 B-2LS Bearing

In automotive settings, 319440 B-2LS Bearing supports large drivetrain components, while in aerospace, its precision fits auxiliary systems. The metric sizing ensures compatibility with a range of international standards.

Essential Roles of 319440 B-2LS Bearing

319440 B-2LS Bearing is a reliable choice for wind turbine yaw systems, where its static load capacity ensures stability. The temperature range of -30° to 110°C makes it suitable for diverse climatic conditions.

"*" indicates required fields