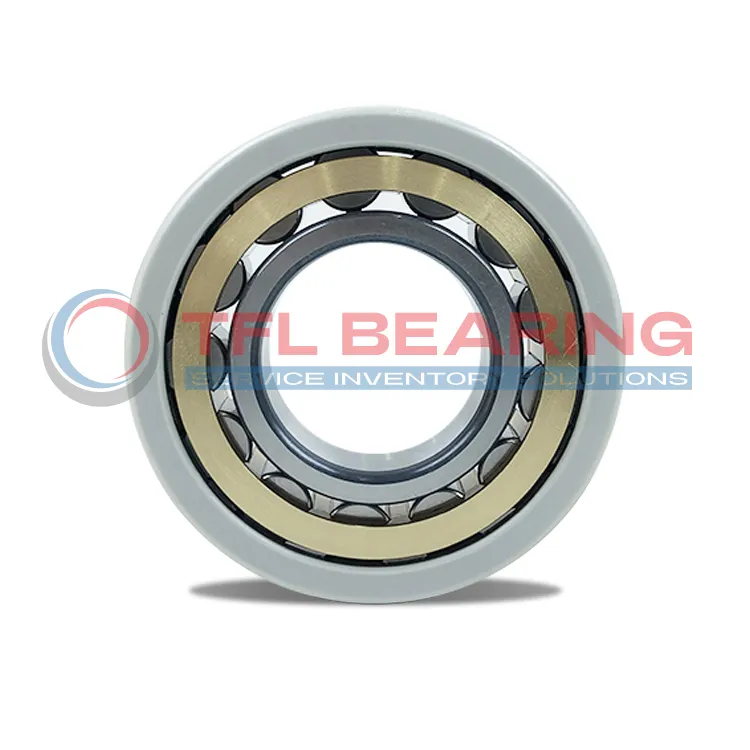

The NJ218-E-XL-M1-F1-J20AA-C4 is a current-insulated cylindrical roller bearing with dimensions of 90mm bore, 160mm outer diameter, and 30mm width. Its outer ring features a ceramic coating to prevent electrical currents, making it ideal for electric motors.

This bearing handles dynamic loads up to 215 kN and spins smoothly at speeds up to 3900 RPM. The brass cage ensures durability, while the C4 radial clearance allows for thermal expansion in demanding conditions.

The ceramic coating provides insulation with a breakdown voltage of up to 1000V, even in damp environments. It’s compliant with RoHS and REACH standards for safe industrial use.

Weighing 2.64kg, it’s a robust choice for applications like wind turbines or industrial drives where electrical insulation is crucial. The design ensures long service life with minimal maintenance.

"*" indicates required fields

How Is NJ218-E-XL-M1-F1-J20AA-C4 Bearing Engineered for Reliability?

NJ218-E-XL-M1-F1-J20AA-C4 Bearing features an outer ring ceramic coating, providing excellent current insulation.

This design prevents electrical arcing, ensuring reliable operation in electrically charged environments.

The brass cage maintains proper roller alignment, reducing friction and wear.

With a basic dynamic load rating of 215 kN, it handles heavy radial loads efficiently.

NJ218-E-XL-M1-F1-J20AA-C4 Bearing operates smoothly at speeds up to 3900r/min.

Its C4 radial internal clearance allows for thermal expansion in high-temperature applications.

The coating offers high electrical resistance, with 50MΩ when dry and 10MΩ in damp conditions.

This makes NJ218-E-XL-M1-F1-J20AA-C4 Bearing suitable for various industrial environments.

Industrial Uses of NJ218-E-XL-M1-F1-J20AA-C4 Bearing

NJ218-E-XL-M1-F1-J20AA-C4 Bearing is commonly used in electric motors and generators, where its current-insulating coating prevents electrical arcing. The brass cage ensures smooth operation even under high rotational speeds.

In wind turbine systems, NJ218-E-XL-M1-F1-J20AA-C4 Bearing handles radial loads efficiently while resisting electrical damage. Its ceramic-coated outer ring adds durability in harsh outdoor conditions.

For railway applications, NJ218-E-XL-M1-F1-J20AA-C4 Bearing supports axle boxes, providing reliable performance under heavy loads. The C4 clearance allows for thermal expansion during long-distance travel.

Where Is NJ218-E-XL-M1-F1-J20AA-C4 Bearing Used?

NJ218-E-XL-M1-F1-J20AA-C4 Bearing fits well in industrial pumps, where its insulation properties protect against stray currents. The high dynamic load rating ensures longevity in continuous operation.

In conveyor systems, NJ218-E-XL-M1-F1-J20AA-C4 Bearing reduces downtime with its robust design. The M1 suffix indicates optimized internal geometry for better load distribution.

Built for Heavy-Duty Use: NJ218-E-XL-M1-F1-J20AA-C4 Bearing

NJ218-E-XL-M1-F1-J20AA-C4 Bearing excels in steel mill equipment, handling both radial and axial forces. Its 200 µm insulating layer withstands frequent electrical exposure.

For mining machinery, NJ218-E-XL-M1-F1-J20AA-C4 Bearing offers reliable performance in dusty environments. The ceramic coating resists wear from abrasive particles.

Automotive vs Aerospace: Applications of NJ218-E-XL-M1-F1-J20AA-C4 Bearing

In automotive alternators, NJ218-E-XL-M1-F1-J20AA-C4 Bearing prevents electrical damage from variable loads. Its compact design fits easily into tight engine spaces.

For aerospace actuators, NJ218-E-XL-M1-F1-J20AA-C4 Bearing provides precision movement with minimal maintenance. The high reference speed suits demanding flight conditions.

"*" indicates required fields