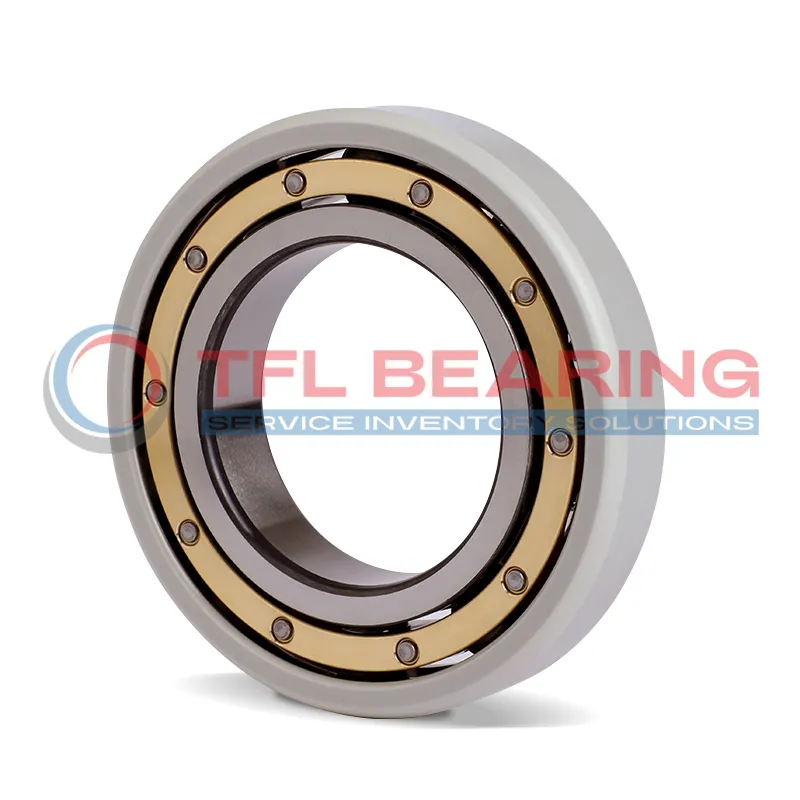

The FAG NU220-E-M1-J20AA-C3 is a current-insulated cylindrical roller bearing with a 100mm bore and 180mm outer diameter, designed to prevent electrical damage. Its outer ring features a ceramic coating (J20AA) for insulation, with a breakdown voltage of up to 1000V.

This bearing handles dynamic loads up to 295 kN and static loads up to 305 kN, making it suitable for heavy-duty applications. It operates smoothly at speeds up to 3450 RPM and works in damp conditions with an electrical resistance of 10MΩ.

The brass cage ensures durability, while the C3 radial clearance allows for thermal expansion. It’s ideal for electric motors or generators where current leakage is a concern.

Weighing 3.83 kg, it’s robust yet manageable. Compliant with RoHS and REACH standards, it’s a reliable choice for industrial use.

"*" indicates required fields

Why Choose NU220-E-M1-J20AA-C3 Bearing for Precision Tasks?

NU220-E-M1-J20AA-C3 Bearing features an outer ring ceramic coating, providing excellent electrical insulation.

This design prevents current passage, reducing the risk of damage in electrical applications.

The brass cage ensures smooth operation and alignment of rollers, enhancing performance under heavy loads.

With a basic dynamic load rating of 295 kN, it handles demanding industrial conditions with ease.

NU220-E-M1-J20AA-C3 Bearing operates efficiently at speeds up to 3450r/min, offering reliable performance.

Its C3 radial internal clearance allows for thermal expansion, ensuring stability in varying temperatures.

The coating provides high electrical resistance, with 50MΩ when dry and 10MΩ in damp conditions.

This makes NU220-E-M1-J20AA-C3 Bearing suitable for environments where electrical insulation is crucial.

Industrial Uses of NU220-E-M1-J20AA-C3 Bearing

NU220-E-M1-J20AA-C3 Bearing is commonly used in electric motors and generators, where its current-insulating properties prevent electrical damage. The ceramic coating on the outer ring ensures reliable performance in high-voltage environments.

In wind turbine applications, NU220-E-M1-J20AA-C3 Bearing handles heavy radial loads while maintaining electrical insulation. Its brass cage provides added durability in fluctuating weather conditions.

For industrial pumps, NU220-E-M1-J20AA-C3 Bearing offers stable operation with its C3 radial clearance. The coating also resists moisture, making it suitable for damp environments.

What Makes NU220-E-M1-J20AA-C3 Bearing a Preferred Choice?

NU220-E-M1-J20AA-C3 Bearing is ideal for railway traction motors due to its ability to withstand electrical currents. The ceramic layer ensures long-term reliability even under constant vibration.

In CNC machinery, NU220-E-M1-J20AA-C3 Bearing supports high-speed spindles without electrical interference. Its brass cage reduces friction, enhancing precision during operation.

Optimized for Performance: NU220-E-M1-J20AA-C3 Bearing

NU220-E-M1-J20AA-C3 Bearing works well in marine applications, where damp conditions are common. The insulating coating prevents corrosion from stray currents, extending bearing life.

For conveyor systems, NU220-E-M1-J20AA-C3 Bearing handles heavy loads while maintaining electrical safety. Its robust design ensures minimal maintenance in continuous operation.

Automotive vs Aerospace: Applications of NU220-E-M1-J20AA-C3 Bearing

In hybrid vehicles, NU220-E-M1-J20AA-C3 Bearing is used in electric drivetrains to prevent current leakage. Its high dynamic load rating suits demanding automotive conditions.

For aircraft auxiliary systems, NU220-E-M1-J20AA-C3 Bearing provides reliable insulation against electrical interference. The lightweight design helps meet aerospace weight restrictions.

"*" indicates required fields