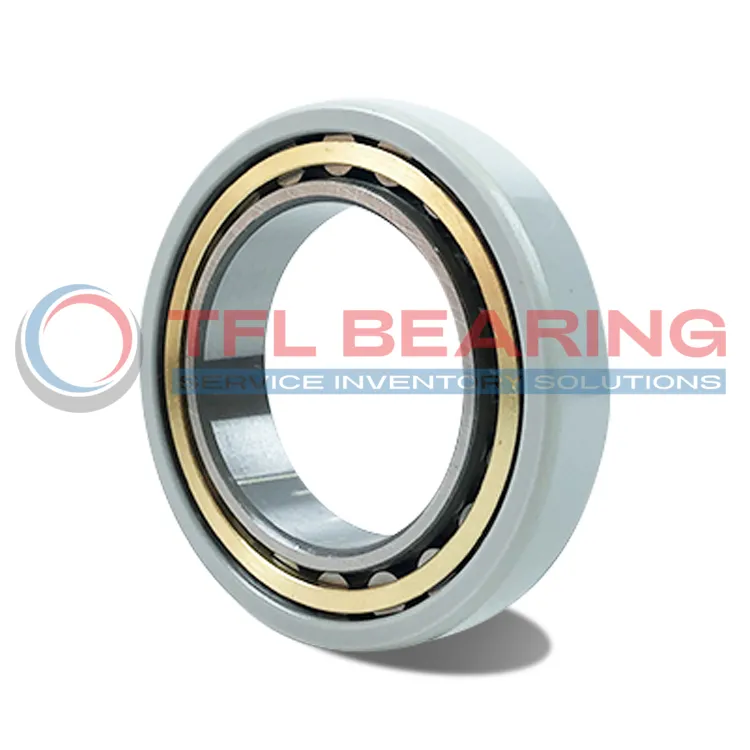

The FAG NU1030-M1-J20AA-C3 is a current-insulated cylindrical roller bearing with dimensions of 150mm bore, 225mm outer diameter, and 35mm width. Its outer ring features a ceramic coating to prevent electrical currents from damaging the bearing.

This model handles dynamic loads up to 248 kN and static loads up to 310 kN, with a reference speed of 3100 RPM. The brass cage provides durability and smooth operation under high-speed conditions.

The insulating coating offers protection with a breakdown voltage of up to 1000V, making it suitable for electric motors or generators. It maintains performance in damp conditions with an electrical resistance of 10MΩ.

Weighing 4.9kg, this bearing is ROHS and REACH compliant. Ideal for industrial applications where electrical insulation is required, such as wind turbines or railway systems.

"*" indicates required fields

How Is NU1030-M1-J20AA-C3 Bearing Engineered for Reliability?

NU1030-M1-J20AA-C3 Bearing features an outer ring ceramic coating, providing excellent current insulation for electrical applications.

Its brass cage ensures smooth operation and durability, even under high dynamic loads of 248 kN.

With a reference speed of 3,100 rpm, it delivers reliable performance in demanding industrial environments.

The C3 radial internal clearance allows for thermal expansion, enhancing longevity.

What Makes NU1030-M1-J20AA-C3 Bearing Suitable for High-Temperature Applications?

NU1030-M1-J20AA-C3 Bearing’s ceramic-coated outer ring resists electrical currents and withstands high temperatures.

The brass cage maintains stability, even under heavy loads, ensuring consistent performance.

Its breakdown voltage of ≤1,000V makes it ideal for electrically challenging conditions.

With a static load rating of 310 kN, it handles demanding industrial applications with ease.

Built for Reliability: NU1030-M1-J20AA-C3 Bearing

NU1030-M1-J20AA-C3 Bearing is designed with a brass cage for enhanced durability and smooth operation.

The ceramic coating on the outer ring prevents electrical arcing, protecting machinery.

Its C3 clearance accommodates thermal expansion, reducing wear over time.

With a dynamic load rating of 248 kN, it excels in high-performance settings.

Steel vs Ceramic Bearings: Strengths of NU1030-M1-J20AA-C3 Bearing

NU1030-M1-J20AA-C3 Bearing combines ceramic-coated insulation with robust steel construction for superior performance.

The brass cage ensures precise alignment of rollers, minimising friction and wear.

Its high breakdown voltage and electrical resistance make it ideal for motor applications.

With a width of 35 mm, it fits compact spaces while delivering strong load capacity.

Industrial Uses of NU1030-M1-J20AA-C3 Bearing

NU1030-M1-J20AA-C3 Bearing is commonly used in electric motors and generators, where its current-insulating coating prevents electrical damage. The brass cage ensures smooth operation even under high rotational speeds.

Where Is NU1030-M1-J20AA-C3 Bearing Used?

In wind turbines, NU1030-M1-J20AA-C3 Bearing handles radial loads efficiently while its ceramic coating protects against stray currents. Its C3 clearance makes it suitable for applications with thermal expansion.

Built for Heavy-Duty Use: NU1030-M1-J20AA-C3 Bearing

NU1030-M1-J20AA-C3 Bearing excels in industrial gearboxes, offering reliable performance under heavy loads. The brass cage and ceramic coating extend its lifespan in harsh environments.

Automotive vs Aerospace: Applications of NU1030-M1-J20AA-C3 Bearing

In automotive drivetrains, NU1030-M1-J20AA-C3 Bearing supports high radial loads, while in aerospace, its insulation properties are vital for avionics systems. The 35mm width fits compact designs.

Perfect Fit for Automation: NU1030-M1-J20AA-C3 Bearing

NU1030-M1-J20AA-C3 Bearing is ideal for robotic arms in automated production lines, where precision and electrical insulation are key. Its 248 kN dynamic load rating ensures durability.

"*" indicates required fields