Have you ever wondered why your bike glides so smoothly or how cars travel with less effort? When you ride or drive, friction tries to slow things down and waste energy. You need less friction for better speed and efficiency. In fact, experts report that friction accounts for about one-third of fuel use in heavy vehicles. Thanks to advances in technology, new ball bearings help save fuel, cut emissions, and support green mobility. As more vehicles hit the road, the demand for better friction reduction keeps rising.

Key Takeaways

- Ball bearings reduce friction by changing sliding friction into rolling friction, making bikes and cars move smoother and use less energy.

- The small metal balls inside bearings touch surfaces at tiny points, lowering resistance and wear for longer-lasting parts.

- Lubricants like grease or oil help ball bearings work better by reducing metal contact and heat, which extends their life.

- In bikes, ball bearings help wheels, pedals, and steering parts turn easily, giving you a smoother and more efficient ride.

- In cars, ball bearings support wheels, transmissions, engines, and suspension, improving fuel efficiency, comfort, and durability.

What Are Ball Bearings?

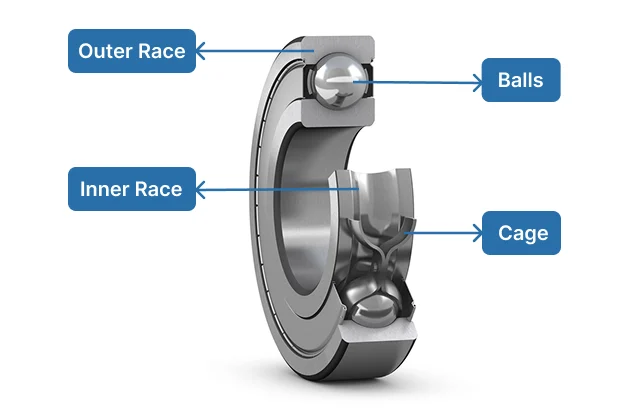

Definition and basic structure: inner race, outer race, balls, and cage

You can think of ball bearings as small but powerful helpers inside your bike or car. Each ball bearing has four main parts. The inner race sits at the center and rotates with the shaft. The outer race stays fixed to the housing. Between these two rings, you find several small metal balls. A cage holds the balls in place and keeps them evenly spaced. This simple design lets the balls roll smoothly between the races.

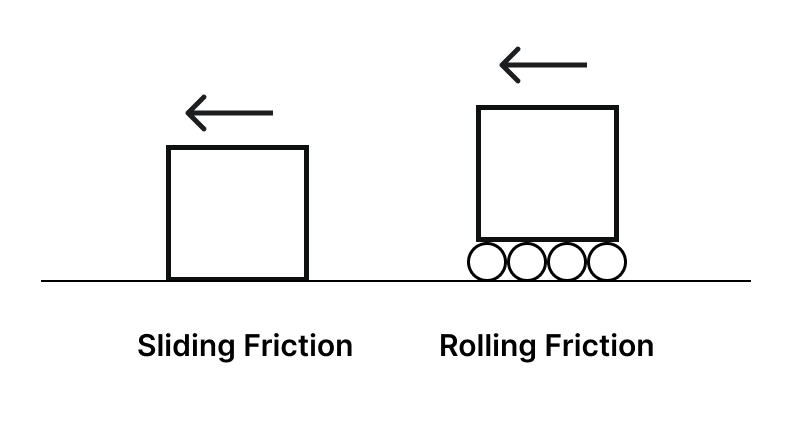

Principle of operation: converting sliding friction into rolling friction

When you use a bike or drive a car, you want parts to move with as little resistance as possible. Ball bearings help by turning sliding friction into rolling friction. Sliding friction happens when two flat surfaces rub against each other. Rolling friction is much lower because the balls roll instead of slide. This means you use less energy to move, and your ride feels smoother.

Tip: Rolling friction is always less than sliding friction. That is why ball bearings make such a big difference in how things move.

Overview of common types

You will find many types of ball bearings in the world. The most popular type is the deep-groove ball bearing. It is strong, versatile, and works well in many machines. In fact, deep-groove ball bearings made up about 43.7% of the global market in 2023. The automobile industry uses almost half of all ball bearings, showing how important they are for cars and trucks. Here is a quick look at where you might find them:

- Cars and trucks (largest share)

- General engineering

- Mining and construction

- Railways and shipping

- Aerospace and agriculture

| Category | Segment/Application | Market Share / Statistic | Year | Notes |

|---|---|---|---|---|

| Application | Automotive | 49.2% | 2023 | Largest market share globally; driven by vehicle production and demand for moving parts |

| Type | Deep-Groove Ball Bearings | 43.7% | 2023 | Most widely used type due to versatility and durability |

| U.S. Market Size | Ball Bearing Market | USD 8.2 Billion | 2024 | Automobile segment accounts for majority of market share |

You can see that ball bearings play a key role in many industries, especially in vehicles.

How Ball Bearings Reduce Friction

Comparison: sliding friction vs rolling friction

You can feel the difference between sliding and rolling friction every time you move a heavy object. When you push a box across the floor, it takes a lot of effort because the surfaces slide against each other. If you place the box on rollers, it moves much easier. Ball bearings work in a similar way. They replace sliding friction with rolling friction, which is much lower. This change means you need less force to move parts, so your bike or car runs smoother and faster.

Role of the ball elements in reducing contact area

The balls inside the bearing play a key role in reducing friction. Each ball touches the inner and outer rings at only a small point. This tiny contact area means less surface rubs together, which lowers resistance. You get more efficient movement and less wear on the parts. Engineers use advanced models and experiments to study how these balls reduce friction. They look at frictional torque, temperature, and wear patterns to design better bearings.

Did you know? Studies show that surface roughness, lubrication, and material choice all help ball bearings cut down friction and wear.

Use of lubricants to further minimize friction

Lubricants make ball bearings even more effective. When you add grease or oil, it forms a thin layer between the metal parts. This layer reduces metal-to-metal contact and spreads the load evenly. Tests measure frictional torque and temperature to see how well lubricants work. For example, the ASTM D4170 standard checks how much wear happens under heavy loads. The right lubricant keeps friction and heat low, which helps your bearings last longer.

Reduction of heat generation and energy waste

Lower friction means less heat builds up inside your bike or car. When ball bearings roll smoothly, they waste less energy as heat. This keeps parts cooler and prevents damage. You get better performance and save energy at the same time. Engineers use both experiments and computer models to measure how much heat and energy ball bearings save. These tools help them create bearings that last longer and work more efficiently.

Ball Bearings in Bikes

Ball bearings play a key role in making your bike ride smooth and efficient. You find them in several important parts of your bike. Each part relies on these small components to help you move with less effort and more control.

Wheels

When you spin your bike wheels, you want them to turn freely and quickly. Ball bearings inside the wheel hubs make this possible. They let the wheels rotate with very little resistance. You use less energy to pedal, and your bike glides farther with each push. If you keep the bearings clean and well-lubricated, your wheels will last longer and stay smooth. Experts say that the right type and amount of grease matter more than just how hard the grease is. Too much grease can make the balls slide instead of roll, while too little can cause wear. Regular maintenance helps your wheels perform at their best.

Tip: Clean and lubricate your wheel hubs often to keep your ride smooth and fast.

Pedals and Cranksets

Pedals and cranksets also depend on ball bearings for smooth movement. When you push down on the pedals, the bearings let them spin easily. This means you waste less energy and get more power with each stroke. The crankset, which connects your pedals to the chain, uses bearings to turn smoothly as well. Good bearings in these parts help you ride longer without feeling tired. They also protect the parts from wearing out too soon.

Headsets and Brackets

The headset connects your handlebars to the bike frame. Ball bearings in the headset let you steer with less effort. You feel more control and stability, especially when turning or riding over bumps. Bottom brackets, found where the crank arms meet the frame, use bearings to support the crankset. These bearings handle a lot of force every time you pedal. Advanced technologies, like solid lubrication in some bearings, keep them running smoothly even under tough conditions. For example, some new bearings use a solid oil-infused polymer that keeps out dirt and keeps the parts lubricated. In tests, these bearings lasted much longer than traditional ones, especially in parts like headsets and suspension pivots where grease can get pushed away.

Note: Bearings with advanced lubrication can last up to three times longer than standard ones, giving you more time on the road and less time in the shop.

Ball bearings in your bike do more than just help parts spin. They give you a stable ride, absorb shocks from rough roads, and help you transfer power from your legs to the wheels. When you take care of your bearings, you enjoy a smoother, safer, and more efficient ride.

Ball Bearings in Cars

Ball bearings help your car run smoothly and last longer. You find them in many important parts of your vehicle. They handle heavy loads, reduce friction, and keep everything moving with less effort. Let’s look at how they work in different car systems.

Wheels

You rely on wheel bearings every time you drive. These ball bearings sit inside the wheel hubs. They let your wheels spin with very little resistance. When you turn the steering wheel or hit a bump, the bearings absorb shocks and keep your ride stable. You get better control and a quieter drive. Modern wheel bearings use advanced materials like ceramics and special coatings. These upgrades help your car handle higher speeds and heavier loads. Some new bearings even last four to eight times longer than older types. They resist rust and keep working well, even in tough weather.

Tip: If you hear a humming or grinding noise from your wheels, it might be time to check your bearings.

Transmission and Gears

Your car’s transmission uses ball bearings to help gears turn smoothly. These bearings cut down on friction between moving parts. You shift gears more easily and lose less energy as heat. Engineers use strict standards, like ABMA Standard 9 and ISO 281, to test how much load these bearings can handle. They also use new models to measure drag forces and pressure inside the bearings. This research helps make transmissions more efficient and reliable. When you have good bearings in your transmission, you get better fuel economy and smoother gear changes.

Engine and Accessories

Ball bearings play a big role in your engine and its accessories. You find them in alternators, pulleys, clutches, and even the air conditioning compressor. These parts spin at high speeds and need to stay cool. Bearings with smart sensors can now track temperature and wear in real time. This technology helps you spot problems early and avoid breakdowns. Some bearings use eco-friendly materials that save energy and can be recycled. Hybrid and ceramic bearings last longer and work well even without much oil. You spend less on repairs and keep your engine running strong.

| Component | Bearing Benefit | Extra Feature |

|---|---|---|

| Alternator | Smooth rotation | Sensors for monitoring |

| Pulley | Low friction | Ceramic or hybrid materials |

| AC Compressor | Quiet operation | Eco-friendly design |

| Clutch | Fast response | High-speed capability |

Suspension and Comfort

Your car’s suspension system uses ball bearings to help absorb bumps and keep your ride comfortable. These bearings sit in shock absorbers and other moving joints. They handle both up-and-down and side-to-side forces. When you drive over rough roads, the bearings help cushion the impact. You feel less vibration and noise inside the car. New manufacturing methods, like 3D printing and Industry 4.0, make it possible to create custom bearings for each car model. These advances give you a smoother, safer, and more enjoyable ride.

- Advanced ball bearings in cars offer many benefits:

- Handle heavy loads and high speeds

- Reduce energy use and fuel costs

- Last longer and need less maintenance

- Improve comfort and safety

Note: Studies show that hybrid and ceramic bearings not only last longer but also help your car use less energy. They keep your vehicle running smoothly, even in tough conditions.

Advances and Innovations

New materials such as ceramic ball bearings

You see many new materials changing how bearings work today. Ceramic bearings stand out because they are lighter and harder than steel. These bearings resist heat and wear, so they last longer and spin faster. Manufacturers also use ultra-clean steel with fewer impurities. This steel helps reduce noise and makes bearings more reliable. Some companies use high-nitrogen steel for even better noise control. Stainless steel bearings fight rust, which is important if you ride or drive in wet places. In some cases, engineers use plastics or other special materials for extreme conditions.

| Innovation Area | Key Advancements and Benefits |

|---|---|

| Materials | Ultra-clean steel, ceramics, plastics, and stainless steel for better performance and durability |

Sealed bearings and automatic lubrication systems

Sealed bearings help keep dirt and water out. You get longer life and less maintenance. Grease inside the seal protects against rust and keeps everything running smoothly. Studies show that grease lubrication with good seals reduces leaks and boosts reliability. Some seals now have sensors that watch for wear and send real-time data. This helps you spot problems early and avoid breakdowns. Automatic lubrication systems take care of the grease for you. These systems use sensors and controllers to add just the right amount of lubricant. You save time and reduce waste. Newer systems even connect to smart devices for easier monitoring.

Tip: Sealed bearings and automatic lubrication systems help you spend less time on repairs and more time enjoying your ride.

Trends toward higher efficiency and durability

You notice that bearings keep getting smaller, lighter, and stronger. Companies use computer simulations to design better shapes and test how long bearings will last. Some factories use artificial intelligence and machine learning to improve quality and speed up production. Smart bearings can now track their own performance and warn you before something goes wrong. These changes mean you get parts that last longer, use less energy, and work better in tough conditions. The industry also focuses on sustainability by using less material and making products that are easier to recycle.

You see the results of friction reduction every time you ride or drive. Bearings help your bike and car move smoothly, save energy, and last longer. Industry reports show that new materials and smart designs improve efficiency and durability across many fields.

| Sector | Benefit |

|---|---|

| Automotive | Lower emissions, longer part lifespan |

| Aerospace | Handles high speeds and extreme conditions |

| Industrial | Reduces downtime and maintenance costs |

If you want a smoother, more reliable ride, explore quality bearings from TFL Bearings.

FAQ

How often should you lubricate ball bearings on your bike?

You should check and lubricate your bike’s ball bearings every few months. If you ride in wet or dusty places, do it more often. Clean bearings last longer and help your bike run smoothly.

Tip: Listen for squeaks or grinding. These sounds mean your bearings need attention.

Can you replace ball bearings yourself?

Yes, you can replace ball bearings at home with basic tools. You need patience and care. Always follow your bike or car manual. If you feel unsure, ask a mechanic for help.

- Tools you may need:

- Wrenches

- Grease

- Clean cloth

What happens if ball bearings fail?

If ball bearings fail, you may hear grinding noises or feel rough movement. Your wheels or parts may wobble. This can cause damage to other parts and make your ride unsafe.

| Warning Signs | What You Notice |

|---|---|

| Noise | Grinding or humming |

| Movement | Wobbling or stiffness |

Are ceramic ball bearings better than steel ones?

Ceramic ball bearings weigh less and resist heat better than steel. You get smoother rides and longer life. They cost more, but you may save money over time.

Note: Many racers and high-performance bikes use ceramic bearings for speed and durability.