Introduction: The Two Giants in the Bearing World

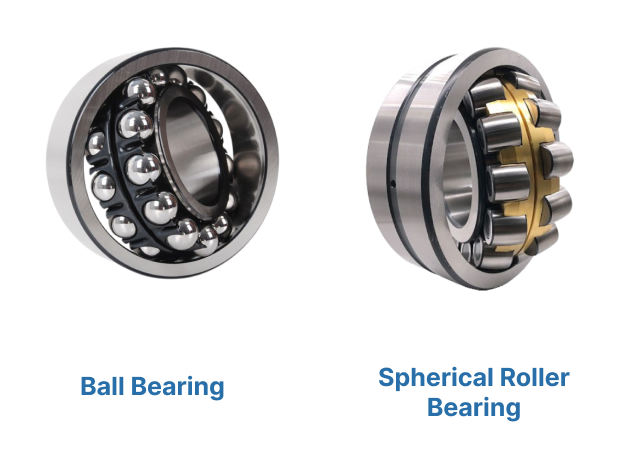

Have you ever wondered about something interesting in the world of bearings? Spherical roller bearings look a bit different from regular roller bearings. Their rolling elements feature a unique spherical design, which might remind you of ball bearings at first glance. So, what exactly sets spherical roller bearings apart from ball bearings? Let’s explore this fascinating topic together!

| Feature | Spherical Roller Bearings | Ball Bearings |

| Load Capacity | High to extremely high radial and bidirectional axial loads | Light to medium radial and axial loads |

| Speed Capability | Suitable for medium-speed applications | Suitable for high-speed applications |

| Self-Aligning Ability | Excellent self-aligning capability | Limited (except for self-aligning ball bearings) |

| Friction & Heat | Higher friction (optimized in modern designs), relatively more heat generation | Low friction and minimal heat generation |

| Durability & Robustness | Rugged and durable; ideal for harsh environments and shock loads | Suitable for expected loads, sensitive to heavy shocks and extreme contamination |

| Typical Applications | Vibrating screens, rolling mills, wind turbines, heavy construction/mining equipment | Electric motors, household appliances, precision instruments, light conveyors |

| Maintenance Needs | Re-lubricable, maintenance requirements can be reduced | Generally low, many sealed types are lubricated for life |

| Noise & Vibration | Tolerates some noise and vibration, but offers stable performance | Low noise and vibration; ideal for precision use |

Actually, spherical roller bearings excel in heavy-load, medium-to-low-speed environments. They offer a longer service life and outstanding self-aligning capabilities. On the other hand, ball bearings aren’t designed for heavy loads but perform exceptionally well at high speeds. They also provide a long service life under light loads, though their self-aligning ability is more limited.

Spherical Roller Bearings and Ball Bearings

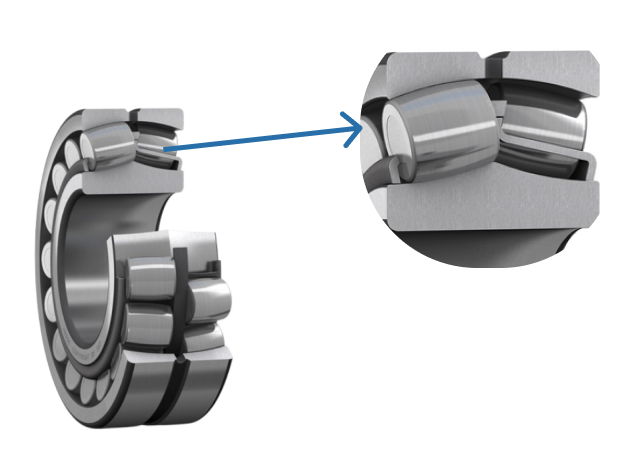

What are spherical roller bearings?

Spherical roller bearings were first invented and patented by Arvid Palmgren in 1919, later introduced to the market by SKF.

Compared to ordinary roller bearings, their standout feature is the unique shape of the rolling elements—neither cylindrical nor perfectly spherical, but more like a slightly overinflated cylinder. This design allows them to automatically adjust for misalignment or distortion in the shaft or bearing housing, making them indispensable in certain applications.

If you’re dealing with potential shaft deflection, bearing housing deformation, or assembly challenges, spherical roller bearings often provide the best solution.

Additionally, these bearings come in various types and designs to suit different needs. For example, sealed versions with integral seals help protect against contaminants, split designs make assembly and disassembly easier, and different cage materials (such as steel, brass, or polyamide) offer flexibility depending on your application.

What are ball bearings?

Ball bearings represent a broad category of bearings that reduce friction through the movement of spherical rolling elements between the inner and outer rings.

The significant advancements in ball bearing technology began during the Renaissance. Leonardo da Vinci sketched one of the first designs for a ball bearing in the 15th century. However, it wasn’t until the late 19th and early 20th centuries that ball bearings became widely used in industrial applications.

Today, ball bearings are available in many types to meet specific needs:

- Deep groove ball bearings: These are the most common type, capable of handling both radial and axial loads while offering high-speed performance, low friction, and minimal noise. They’re also easy to install and maintain.

- Angular contact ball bearings: Designed to handle combined radial and axial loads, they have a high load-carrying capacity thanks to an angle formed by the relative displacement of the inner and outer rings.

- Self-aligning ball bearings: Featuring two rows of steel balls and a spherical raceway on the outer ring, they can accommodate slight misalignments between the shaft and bearing housing while reducing friction.

- Thrust ball bearings: Specifically designed for axial forces, they support heavy loads along the axis of rotation and prevent unwanted axial movement.

- Miniature/super-miniature ball bearings: Compact and lightweight, these bearings are ideal for space-constrained applications, providing smooth, quiet, and high-speed operation.

Thanks to their simple yet versatile design, ball bearings are widely used across industries, including electric motors, gearboxes, rotary encoders, medical equipment, pumps, printing presses, textile machinery, and household appliances like washing machines, vacuum cleaners, and air conditioners.

The Differences Between Spherical Roller Bearings and Ball Bearings

We’ve already outlined the main differences between spherical roller bearings and ball bearings in the table at the beginning. Now, let’s take a closer look at why these differences matter:

Load Capacity

- Spherical Roller Bearings: These bearings benefit from the linear contact typical of roller bearings, allowing them to distribute and handle extremely heavy radial loads effectively. Thanks to their spherical design, they can also manage a certain amount of axial load.

- Ball Bearings: Ball bearings are better suited for applications with light to medium loads. This is because the rolling elements make point contact with the raceway, resulting in a smaller load distribution area. While some types (like deep groove ball bearings and angular contact ball bearings) can handle combined loads, their overall load capacity is generally lower than that of spherical roller bearings.

Speed Capabilities

- Spherical Roller Bearings: Due to their larger contact area from linear contact, these bearings tend to generate more friction at high speeds. Although modern technology has improved their performance, they’re still best suited for medium and low-speed operations.

- Ball Bearings: With less friction due to their point contact, ball bearings excel in high-speed applications.

Misalignment Accommodation

- Spherical Roller Bearings: These bearings shine when it comes to self-aligning capabilities. They can tolerate significant angular misalignment and shaft deflection without affecting performance or increasing stress, making them ideal for demanding applications.

- Ball Bearings: Standard ball bearings have limited misalignment tolerance. While self-aligning ball bearings do exist, they’re typically used for radial loads and minimal axial loads. Their ability to handle misalignment isn’t as robust as that of spherical roller bearings.

Friction and Heat Generation

- Spherical Roller Bearings: The larger contact area means these bearings may produce more friction than ball bearings, especially at higher speeds.

- Ball Bearings: Thanks to their point contact, ball bearings generate less friction and heat, making them well-suited for precision applications.

Lifespan

- Spherical Roller Bearings: Like most roller bearings, they offer excellent durability in harsh environments, heavy-duty applications, and situations involving heavy impacts.

- Ball Bearings: Ball bearings perform well in their intended applications—light-load, high-speed scenarios—but their lifespan can be significantly reduced under heavy impacts or extreme contamination.

Maintenance Requirements

- Spherical Roller Bearings: These bearings often reduce maintenance needs, particularly when sealed or self-lubricating designs are used.

- Ball Bearings: Ball bearings usually require less maintenance, especially when sealed or dust-proof versions are chosen. Many are lubricated for life, minimizing upkeep.

Cost

Bearings vary widely in price due to factors like size, material, and manufacturer. It’s important to note that direct comparisons aren’t always possible. Beyond the initial cost of the bearing itself, users should also consider long-term expenses such as maintenance and potential replacements. In some cases, higher-priced bearings can offset these costs through superior performance and longevity.

If you’re looking to replace your bearings, we’d love to help! At TFL Bearing, we’re a leading global manufacturer specializing in high-quality, reasonably priced bearings across various types. Whether you need advice on selecting the right bearing or assistance with purchasing, our team is here to support you. Feel free to reach out anytime—we’re ready to find the perfect solution for your needs!

How to Choose the Right Bearing for Your Needs

There isn’t a one-size-fits-all solution when it comes to bearings—each type is designed with a specific application in mind. Choosing the right bearing isn’t just about picking one randomly; it’s a thoughtful process that involves carefully considering various factors.

Below, we’ve compared spherical roller bearings and ball bearings based on some key application considerations: Unfortunately, this content cannot be displayed outside of Feishu Docs at the moment.

| Feature | Spherical Roller Bearings | Ball Bearings |

| Load Capacity | High to extremely high radial and bidirectional axial loads | Light to medium radial and axial loads |

| Speed Capability | Suitable for medium-speed applications | Suitable for high-speed applications |

| Self-Aligning Ability | Excellent self-aligning capability | Limited (except for self-aligning ball bearings) |

| Friction & Heat | Higher friction (optimized in modern designs), relatively more heat generation | Low friction and minimal heat generation |

| Durability & Robustness | Rugged and durable; ideal for harsh environments and shock loads | Suitable for expected loads; sensitive to heavy shocks and extreme contamination |

| Typical Applications | Vibrating screens, rolling mills, wind turbines, heavy construction/mining equipment | Electric motors, household appliances, precision instruments, light conveyors |

| Maintenance Needs | Re-lubricable; maintenance requirements can be reduced | Generally low; many sealed types are lubricated for life |

| Noise & Vibration | Tolerates some noise and vibration, but offers stable performance | Low noise and vibration; ideal for precision use |

When selecting bearings, the principle of “application first” is essential. This means you should start by thoroughly analyzing the specific working conditions and performance requirements of your equipment. By doing so, you can turn technical differences into practical selection criteria, helping you make the best decision for your needs.

Summary:

Compared to ball bearings, spherical roller bearings are ideal for heavy machinery or scenarios where durability and a longer service life are critical, especially in environments that require impact resistance. On the other hand, ball bearings shine in applications that don’t involve heavy loads but demand high speeds and precision. You can choose the bearing type that best matches your specific usage requirements.

If you’re still unsure about which bearing is right for you, feel free to contact us at TFL Bearing. We’re here to provide not only expert purchasing advice but also high-quality bearings tailored to your needs.