Thin wall ball bearings play a vital role in the development of smarter, lighter robots. Their compact size and high precision allow engineers to design robots with less weight and more efficient movement. Thin wall ball bearings set a new standard for space-saving and reliable operation. These bearings help robots achieve smoother motion and greater accuracy. Many robotics teams choose thin section bearings to maximize performance and minimize unnecessary bulk.

Key Takeaways

- Thin wall ball bearings reduce robot weight and size, enabling compact and agile designs.

- Their precise and rigid structure ensures smooth, accurate, and quiet robot movements.

- Advanced sealing options protect bearings from dust and moisture, extending their lifespan.

- These bearings support multiple load types, making them ideal for robotic joints and automation.

- Durable and low-maintenance, thin wall bearings help robots run longer with less downtime.

Thin-Section Ball Bearing Features

Structure

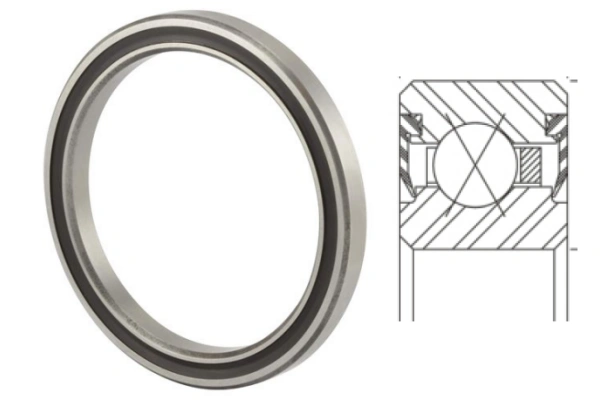

Thin-Walled Sealed Four-Point Contact Ball Bearings set a benchmark for thin-walled ball bearings in robotics. Their structure features a remarkably thin cross-section, which remains constant even as the inner or outer diameter changes. This design allows engineers to create compact and lightweight robotic systems without sacrificing strength or precision.

- Thin wall ball bearings use small diameter steel balls in greater numbers, which reduces friction and increases rigidity.

- The fixed cross-sectional size ensures stable dimensions and consistent performance across different bearing sizes.

- Lightweight construction helps reduce the overall weight of robotic arms and joints.

- High precision and rigidity result from strict manufacturing tolerances.

- The internal geometry minimizes internal losses, leading to smoother rotation and higher efficiency.

Thin wall ball bearings support radial, axial, and moment loads, making them ideal for robotic joints that require both flexibility and strength.

The following table shows key engineering measurements that illustrate the benefits of this structure:

| Measurement | Benefit for Thin wall ball bearings |

|---|---|

| Radial internal clearance | Reduces noise and vibration |

| Preload force | Increases stiffness |

| Torque (starting/running) | Improves efficiency |

| Noise levels (Anderon meter) | Validates quieter operation |

| Fits (interference/clearance) | Maintains bearing integrity |

Sealing Options

TFL offers advanced sealing technology for its thin-wall ball bearings, ensuring long-lasting performance in demanding environments. Sealing options include RS (single-side contact seal), 2RS (double-side contact seal), RZ (single-side non-contact seal), and 2RZ (double-side non-contact seal). These seals protect the bearing from dust and contaminants, retain lubrication, and extend service life.

- Standard seals use nitrile rubber, with options for silicone rubber and Viton for high-temperature or harsh conditions.

- Sealed thin-wall ball bearings require less maintenance and provide reliable operation over time.

- The advanced sealing system helps keep robotic systems running smoothly and efficiently.

Robotics engineers rely on these features to build smarter, lighter robots that perform with accuracy and durability.

Thin Section Bearings in Robotics

Space and Weight Savings

Thin section bearings have transformed the way engineers design robots. Their slim and lightweight construction allows for more compact robotic systems. Many robotic arms and joints use thin section bearings to fit into tight spaces where traditional bearings would not work. This design reduces the overall size and weight of robots, making them easier to move and more energy efficient.

- In an aerial camera assembly, switching to a thin section bearing reduced the weight from 7 lbs. to 3.8 lbs.

- A radar antenna drive bearing with an integrated gear and coil spring spacers achieved significant weight reduction and improved accuracy in a space-constrained environment.

- Rotary tables and polishing tables that use four-point contact thin section bearings gain high stiffness with minimal deflection, enabling more compact and lightweight designs.

Thin section bearings keep their cross-sectional size constant, even when the bore diameter changes. This feature lets engineers use larger bore sizes without increasing the bearing’s width or thickness. As a result, robots can have stronger joints without adding extra bulk. The compact design of thin section bearings also helps reduce the number of components needed in robotic systems. Fewer parts mean less weight and more reliable operation.

Thin section bearings support space-saving and precision requirements that are critical in robotic applications.

Comparative studies show that robots using thin section bearings have a smaller spatial footprint than those with standard bearings. This space efficiency leads to lighter, more agile robots that can perform complex tasks in confined environments.

Precision and Motion Control

Robots need to move with accuracy and repeatability. Thin section bearings provide the high precision and rigidity required for smooth motion control. Their unique structure, with small rolling elements and a constant cross-section, reduces friction and vibration. This leads to quieter operation and more precise movements.

Thin section bearings play a key role in robotic joints and automation arms. They allow robots to handle radial, axial, and tilting loads at the same time. This flexibility supports complex movements and helps robots perform delicate tasks with confidence. High precision bearings like these ensure that robots can repeat the same motion many times without losing accuracy.

A study on thin-walled bearings in harmonic reducers found that these bearings show unique vibration responses under load. Understanding these dynamics helps engineers detect faults early and maintain the reliability and precision of robotic drives. Improved fault detection means robots can operate longer without unexpected breakdowns.

Thin section bearings also improve energy efficiency. Their lightweight design reduces the power needed to move robotic arms and joints. This efficiency lowers operating costs and extends the life of robotic systems.

- Thin section bearings are widely used in robotic arms, joints, and motion control systems.

- Their compact design and high precision enable efficient and accurate robotic movements.

- Lightweight construction and high rigidity contribute to improved performance in robotics.

Thin section bearings help robots achieve smoother, more controlled motion. They support the demands of modern automation and make advanced robotic applications possible.

Thin Wall Bearings Advantages

Integration Flexibility

Thin wall bearings offer unmatched flexibility for integration in robotic systems. Their constant cross-sectional design allows engineers to select the right bore size without increasing the bearing’s width or thickness. This feature supports compact and lightweight robotic arms, making it easier to fit bearings into tight spaces. KAYDOT’s sealing options, including RS, 2RS, RZ, and 2RZ, further enhance this flexibility by providing tailored protection for different environments.

Engineering studies highlight how thin wall bearings adapt to various robotic configurations. These bearings reduce friction and increase design freedom, supporting both simple and complex robotic joints. In harmonic reducers, for example, the elliptical structure of flexible thin wall bearings improves load capacity and allows for precise motion control. The ability to handle radial, axial, and moment loads in a single, slim package gives designers more options when building advanced robots.

Thin wall bearings help engineers create robots that are lighter, more agile, and capable of performing in diverse applications.

Durability and Maintenance

TFL’s thin wall bearings stand out for their durability and low maintenance needs. Advanced sealing technology keeps out dust and contaminants, while retaining lubrication for longer periods. Laboratory and field tests confirm that these bearings withstand rolling contact fatigue, impact, and heavy loads. Bearings with special coatings or treatments, such as SlipCoat, last much longer than untreated ones, sometimes running over 6000 hours without visible damage.

Self-lubricating thin wall bearings also reduce the need for regular maintenance. These bearings use advanced materials and lubrication systems that prevent premature wear and contamination. They operate reliably in harsh environments, including vacuum and dirty settings, where traditional grease-based bearings would fail. This reliability means less downtime and lower maintenance costs for robotic systems.

- Self-lubricating designs eliminate frequent re-lubrication.

- Advanced seals protect against dust, dirt, and moisture.

- Long service life reduces the need for replacement and repair.

Thin wall bearings deliver dependable performance in demanding conditions, helping robots stay operational and efficient for longer periods.

Slim Ball Bearing Applications in Robotics

Robotic Joints

Robotic joints demand high precision and reliability. TFL’s thin-walled sealed four-point contact ball bearings, including the JHA, JA, JB, JU, and JG series, play a vital role in these applications. These bearings support the waist, elbow, and wrist joints in collaborative robots, industrial robots, and mobile robots. Their lightweight design and constant cross-section allow engineers to build compact joints that move smoothly and handle heavy loads.

- UV disinfection robots, developed by teams like MIT and Ava Robotics, use thin wall bearings to achieve efficient joint movement. These bearings reduce friction and weight, making the robots more agile and reliable.

- The bearings offer ample load-carrying capacity, even with a thin profile. This feature supports various joint designs and enables duplexing for higher loads.

- Customization options in cage types, seals, and materials help meet specific requirements for different robotic joints.

The Shadow Robot Company’s Smart Grasping System highlights the impact of thin wall bearings in industrial robots. The system uses precision bearings to ensure consistent joint movement and long service life. Testing confirmed that these bearings provide optimal friction control, which leads to accurate and predictable robot actions. Research on flexible thin-walled bearings in harmonic reducers also shows improved load capacity and fault tolerance, supporting reliable operation in demanding environments.

Automation Systems

Automation technologies rely on dependable motion components. Thin wall bearings from TFL deliver the stiffness and damping needed for high-speed automation. In technical tests, thin wall air bearings supported rotors spinning up to 55,000 rpm. Increased air supply pressure reduced drag and vibration, which extended the operational lifespan of the system. These results confirm that thin wall bearings help automation systems achieve precise, stable, and long-lasting performance.

Automation systems in factories and warehouses benefit from these bearings. Robots equipped with TFL thin wall bearings operate with less downtime and greater efficiency. The advanced sealing options protect against dust and contaminants, ensuring smooth operation in harsh environments. Engineers choose these bearings to enhance the reliability and productivity of modern automation technologies.

Thin wall ball bearings drive innovation in robotics. Thin-Walled Sealed Four-Point Contact Ball Bearings deliver unmatched precision, lightweight design, and durability. These features help robots move smarter and last longer.

- Engineers gain flexibility for compact designs.

- Advanced seals protect against dust and wear.

- Robots achieve higher efficiency and reliability.

TFL Bearings supports engineers with high-quality thin wall bearings. Robotics teams should consider these solutions for their next project.

FAQ

What makes thin wall ball bearings ideal for robotics?

Thin wall ball bearings save space and reduce weight. Engineers use them to design compact robots. These bearings also provide high precision and smooth movement, which are essential for robotic joints and automation systems.

How do TFL’s sealing options improve bearing performance?

TFL offers RS, 2RS, RZ, and 2RZ seals. These seals keep out dust and moisture. They help retain lubrication. This protection extends bearing life and reduces maintenance needs.

Where are thin wall ball bearings most commonly used in robots?

Engineers install thin wall ball bearings in robotic joints, such as the waist, elbow, and wrist. These bearings also appear in automation arms and mobile robots, where space and weight matter most.

How often do thin wall ball bearings require maintenance?

Most thin wall ball bearings need little maintenance. Advanced seals and self-lubricating designs help them last longer. Regular checks ensure optimal performance, especially in harsh environments.