Quick Guide to Read Ball Bearing Codes

Z or ZZ: Metal shields (non-contact, low friction).

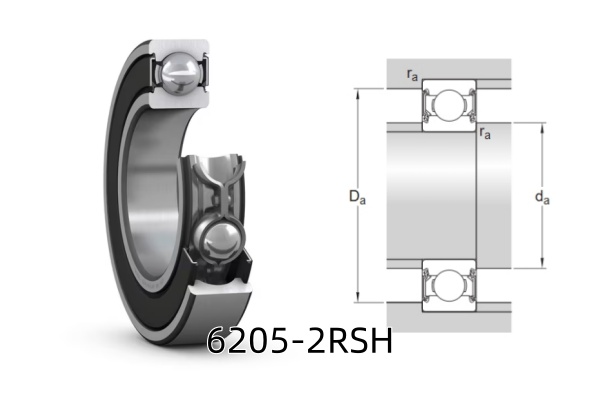

RS or 2RS: Rubber seals (contact, high protection).

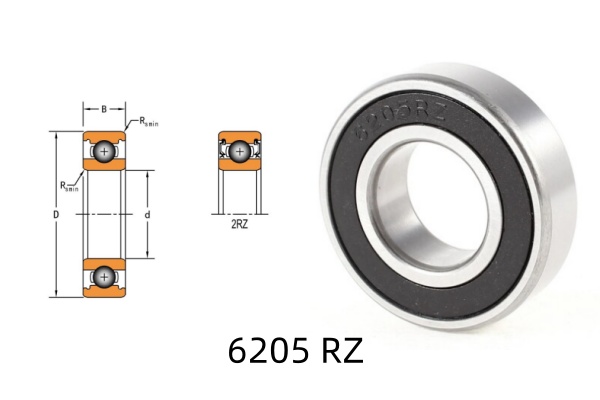

RZ or 2RZ: Low-friction seals (balanced performance).

Single-sided (Z, RS, RZ): Seal on one side only.

Double-sided (ZZ, 2RS, 2RZ): Seals on both sides.

Introduction

Imagine trying to spin something, and it just grinds and shakes. Not good, right? Often, that happens because tiny dirt or grit gets into the moving parts, especially in ball bearings, which are supposed to help things spin easily. Getting dirt or water inside can really hurt a ball bearing fast!

Luckily, there’s a simple answer to keep those little spinning balls safe: seals! They protect the inside of the ball bearing so it can keep working right for a long time.

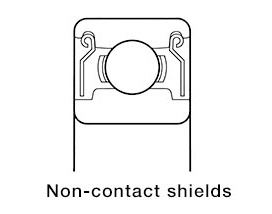

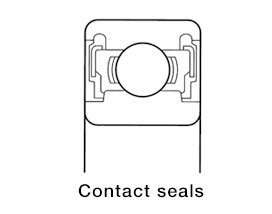

Let’s dive into the three main types of seals you’ll come across: non-contact seals, contact seals, and low-friction seals. We’ll also cover their codes (those letters you see in bearing names like “6205ZZ”) and when to use them.

Non-Contact Seals

Non-contact seals don’t touch the inner part of the bearing, which means they create very little friction. They’re great for machines that need to spin fast, like electric motors or fans, but they’re not the best at keeping out water or fine dust.

Types and Codes

- Metal Shields (Z or ZZ) These are like tiny metal lids that cover one side (Z) or both sides (ZZ) of the bearing. You’ll see codes like 6205Z (one shield) or 6205ZZ (two shields). They’re awesome for keeping out bigger debris, like dirt, in dry environments. Best for: High-speed machines in clean, dry places, like computer fans or skateboards.

- Labyrinth Seals These are special designs that use clever gaps and shapes to block dirt without touching the bearing. They don’t have a standard code and are often custom-made for specific machines. Best for: High-speed, specialized equipment.

Contact Seals

Contact seals are like snug rubber gloves that touch the inner ring of the bearing. They’re fantastic at keeping out dust, water, and grime, but they add a bit more friction, so they’re better for slower or medium-speed machines.

Types and Codes

- Rubber Seals (RS or 2RS) Made of durable rubber (usually nitrile), these seals are coded as RS (one side) or 2RS (both sides). For example, 6205-2RS means a bearing with rubber seals on both sides. They’re perfect for tough conditions, like wet or dusty environments. Best for: Outdoor equipment, like lawnmowers or agricultural machines.

- Reinforced Rubber Seals (RS1 or 2RS1) Some brands, like SKF, offer extra-strong rubber seals with codes like RS1 or 2RS1. These are built for really harsh conditions where extra protection is needed. Best for: Heavy-duty machines in muddy or wet settings.

Low-Friction Seals

Low-friction seals are a middle ground. They touch the bearing lightly, offering decent protection without slowing things down too much. They’re great for machines that need a balance of speed and durability.

Types and Codes

- Low-Friction Rubber Seals (RZ or 2RZ) These seals, coded as RZ (one side) or 2RZ (both sides), are designed to reduce friction while still keeping out some dust and moisture. You might see a bearing like 6205RZ. Best for: Medium-speed machines, like conveyor belts or light-duty motors.

Special Seals

Sometimes, bearings need seals for extreme conditions, like super-hot environments or food-safe machines. Here are a couple of examples:

- High-Temperature Seals (-V or -VT) Made from materials like fluorocarbon rubber, these seals can handle heat. Brands like SKF might use codes like 2RSH/VT. Best for: Ovens or industrial furnaces.

- Food-Grade Seals These are made with materials safe for food processing. The codes vary, so you’ll need to check with the manufacturer. Best for: Food or pharmaceutical equipment.

Choosing the Right Protection for Your Bearing

Picking the right seal depends on where the bearing will be used:

- Clean environment, high speed: Shields (Z, ZZ) might be suitable.

- Dusty or wet environment, moderate speed: Contact seals (RS, 2RS, etc.) offer great protection.

- Environment with some contaminants, higher speed needed: Non-contact seals (RZ, 2RZ, etc.) or low-friction contact seals might be a good compromise.

Conclusion

If you’re trying to replace a bearing or figure out what’s in a piece of equipment, and you don’t have the original box or paperwork, don’t worry! You can really help out a salesperson or someone at the factory by providing clear pictures or even simple drawings of the bearing.

Of course, if you do have the manufacturer’s catalog or datasheet handy, that’s still the most direct way to confirm the codes and specifications!

At TFL, we offer a wide variety of bearings with different seal types to meet your needs. If you’re unsure exactly what you need, don’t hesitate to reach out! Our team is ready to help you identify the correct bearing and seal type based on the information you can provide, ensuring you get the perfect fit for your application.