Home / Product / Ball Bearings / Thrust Ball Bearings / Thrust Ball Bearing With W/ Self Aligning

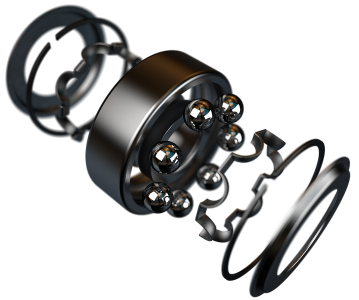

Thrust Ball Bearing With W/ Self Aligning

Thrust ball bearings with self-aligning capabilities are designed to accommodate misalignment between the shaft and housing. These bearings are ideal for applications where shaft deflection or mounting errors may occur. Their ability to ensure smooth operation and extended service life makes them a practical solution for industries prioritizing reliability and performance.

Loading...

Total 27 Results

Part Number

Bore Dia

Outer Dia

Washer Outer Dia

Width

System of Measurement

Bearing Type

For Load Direction

Ring Material

Dynamic Thrust Load

Static Thrust Load

Weight

53309+U309

45 mm

85 mm

90 mm

30.1 mm

Metric

Ball

Thrust

52100 Chrome Steel

17108 lbf

31473 lbf

0.85 kg

53310+U310

50 mm

95 mm

100 mm

34.4 mm

Metric

Ball

Thrust

52100 Chrome Steel

19873 lbf

38892 lbf

1.20 kg

53311+U311

55 mm

105 mm

110 mm

39.3 mm

Metric

Ball

Thrust

52100 Chrome Steel

23380 lbf

46760 lbf

1.68 kg

53312+U312

60 mm

110 mm

115 mm

38.3 mm

Metric

Ball

Thrust

52100 Chrome Steel

22706 lbf

46760 lbf

1.81 kg

53313+U313

65 mm

115 mm

120 mm

39.4 mm

Metric

Ball

Thrust

52100 Chrome Steel

23830 lbf

49458 lbf

1.89 kg

53314+U314

70 mm

125 mm

130 mm

44.2 mm

Metric

Ball

Thrust

52100 Chrome Steel

30349 lbf

67443 lbf

2.51 kg

53315+U315

75 mm

135 mm

140 mm

48.1 mm

Metric

Ball

Thrust

52100 Chrome Steel

36644 lbf

80931 lbf

3.20 kg

Misalignment Tolerance Provided by Self-Aligning Capability

The washers of self-aligning thrust ball bearings feature a spherical raceway surface, with a curvature that matches the centre of the bearing. This allows the bearing to tilt slightly relative to the housing during rotation, providing a degree of freedom in alignment.

Even when there is a certain amount of shaft misalignment or installation error, the self-aligning washer compensates for the deviation and maintains proper contact between the balls and raceways.

As a result, self aligning ball bearings reduce the risk of damage caused by misalignment during installation or operation, improving both the tolerance and reliability of bearing performance.

Easier Maintenance, Longer Service Life

By minimizing the negative effects of misalignment, such as edge loading and uneven stress distribution—the self-aligning capability directly contributes to extending the potential service life of thrust ball bearings with self-alignment.

Reduced wear and smoother operation lead to greater durability and fewer replacements, offering better long-term value for your investment.

Excellent Running Stability

Benefiting from its self-aligning capabilities, even minor installation errors or misalignments caused by rotation during operation, can be effectively compensated by self-aligning thrust bearings, ensuring the equipment continues to run smoothly without disruption.

In addition, most self-aligning thrust bearings use high-quality steel balls. These balls are precisely machined, allowing for smooth motion along the raceways during operation, which contributes to stable and seamless equipment performance.

FREQUENTLY ASKED QUESTIONS

How much misalignment can self aligning thrust ball bearings typically handle?

They are designed to accommodate initial static misalignment, with a typical self-aligning angle of around 2°, and some designs allowing up to 3°–4°. The exact misalignment tolerance depends on the specific model and thrust bearing dimensions.

What materials are available for thrust ball bearing with self aligning?

Most thrust ball bearings with self aligning are made of chrome steel.

Known for its high hardness, excellent wear resistance, and good fatigue strength, chrome steel offers a well-balanced combination of performance, manufacturing maturity, and cost-effectiveness, making it one of the most widely used bearing materials in general machinery applications.

Do thrust ball bearings with self aligning require special bearing housing designs?

In most cases, a special bearing housing design is required. While self-aligning thrust bearings relax the perpendicularity requirements, the bearing seat surface that contacts the spherical thrust washer should have the appropriate shape (typically flat, but it should be verified against the manufacturer's specifications) and provide solid support.

Do your bearings meet international quality standards?

Yes, we are an ISO-certified bearing manufacturer, and all our bearings strictly comply with international quality standards.

OUR PROCESS

Contact

Initial Contact

01

Budgeting

Specialists Review

Needs

02

Options

Our Engineers Help YouChoose The RightBearings

03

Plant Visit

Option To Visit OurManufacturing Plant

04

Delivery

Your entire order is

delivered.

05

Support

We provide ongoingproduct support

06

HOT PRODUCTS

CAN’T FIND WHAT YOU NEED?

Please provide your question.

We’ll find you with the best support options.