Roller bearings sealing structures give important protection in many uses. These sealing devices stop dirt from getting in and keep lubricant inside. Even tiny particles can cause wear, make bearings hotter, and make them not last as long. Good sealing stops outside dirt, so roller bearings last longer and work better. Good sealing also keeps the lubricant clean, which helps roller bearings work smoothly. Different uses need special sealing to give the best protection and performance.

Key Takeaways

Seals help roller bearings by stopping dirt from getting in and keeping lubricant inside. This makes bearings last longer and work better. Contact seals touch moving parts to stop dirt and keep lubricant in. Non-contact seals have small gaps to lower friction and are good for fast machines. Seal materials like rubber, synthetic rubber, and polyurethane have different strengths and can handle different conditions. Picking the right seal type and material helps bearings work well and need fewer repairs. Checking and taking care of seals often stops early problems and helps bearings run smoothly.

Functions

Contaminant Exclusion

Sealing in roller bearings acts like a shield. It keeps out dirt, dust, and water. Seals stop these things from getting inside the bearing. This helps protect the rolling parts and makes the bearing last longer. Most bearing failures happen because of bad mounting, poor sealing, or not enough lubricant. If dirt or small pieces get in, they can scratch or dent the surface. This often causes the bearing to fail early. When seals work well, they keep out dirt. This means the bearing usually fails from inside fatigue, not from surface damage. Bearings last longer this way. New sealing and filtering methods help stop harmful particles from getting in. This lowers the chance of rolling contact fatigue. Experts say keeping out dirt is very important for making roller bearings more reliable.

- Seals keep dirt, dust, and water away from bearing parts.

- Good sealing helps stop failures that start on the surface.

- Strong seals mean you do not need to fix bearings as often.

Lubricant Retention

Seals in roller bearings also help keep the lubricant inside. This is important for making a smooth layer that cuts down friction. It also stops rust from forming. Tests show that bearings last up to three times longer if they stay clean. Bearings made from case carburized steel last longer when there is dirt. Some special bearings can last more than twice as long as normal ones. Seals that keep the lubricant inside help bearings work better and last longer.

- Seals help keep the right amount of lubricant inside.

- Good seals mean you do not need to add lubricant often.

- Strong seals stop lubricant from leaking out.

Performance Impact

How well the seal works changes how the bearing works. Studies show that rubber sealing rings wear out and age. This is a big reason why bearings do not last. Newer seal designs, like grid shapes, help seals last longer. They also slow down aging. Tests show that bad seals cause more shaking, faster wear, and less trust in the bearing. Good seals help the bearing run smoother and use less energy. They also make machines last longer. Seals help you wait longer before fixing things. They also help with real-time checks in smart machines.

Tip: Picking the right seal and making sure it works well can help roller bearings last longer and work better.

Types of Sealing Devices

Roller bearings need good sealing devices to stay safe. These devices stop dirt from getting in and keep lubricant from leaking out. Engineers pick from two main types: contact seals and non-contact seals. Each type works best for different jobs.

Contact Seals

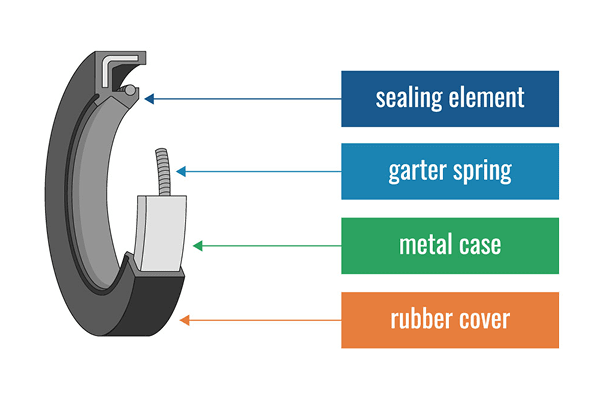

Contact seals touch the bearing or shaft. This touch makes a strong barrier. They block dirt, dust, and water. They also keep the lubricant inside. Contact seals are made from rubber or synthetic rubber. These materials press on moving parts to make a tight seal.

Working Principle:

Contact seals have a soft lip that pushes on the shaft or ring. The lip moves with the shaft and stays close. This keeps out dirt and holds in lubricant.

Advantages:

- Very good at blocking dirt and water

- Great at keeping lubricant inside

- Simple to use and easy to put in

Disadvantages:

- Some friction happens because of the seal

- Can get hot if the bearing spins fast

- The seal can wear out after a while

Typical Applications:

Contact seals are used in tough places. Engineers put them in construction machines and farm tools. They are also in car wheel hubs. These places have lots of dust, mud, or water. Contact seals are used when the most protection is needed.

Note: Low-friction seals are a special kind of contact seal. They lower friction but still block dirt. These seals help roller bearings stay cool and last longer.

Table: Contact Seals at a Glance

| Feature | Benefit | Example Applications |

|---|---|---|

| Tight contact | Blocks dirt and water | Wheel hubs, conveyors |

| Lubricant retention | Extends bearing life | Off-road vehicles |

| Simple structure | Easy to install and replace | Industrial gearboxes |

Non-Contact Seals

Non-contact seals do not touch the shaft or ring. They use a small gap or a tricky path to stop dirt. These include labyrinth seals and shielded designs. Non-contact seals let the bearing spin with almost no drag.

Working Principle:

Non-contact seals use a thin gap or a maze-like path. This makes it hard for dirt or water to get in. Labyrinth seals have grooves and turns to trap dirt. Air and spinning help keep dirt away.

Advantages:

- No friction, so no extra heat

- Lasts a long time

- Good for fast-spinning bearings

Disadvantages:

- Not as good at blocking tiny dust or water

- May not keep lubricant in as well

- Needs to be lined up just right

Typical Applications:

Non-contact seals are best in clean places. Engineers use them in electric motors, fans, and fast machines. These jobs need low drag and long life. Non-contact seals are also used in precision tools.

Tip: Labyrinth seals work well in dusty places. They are used in mining machines and conveyor belts.

Table: Non-Contact Seals at a Glance

| Feature | Benefit | Example Applications |

|---|---|---|

| No physical contact | No heat from seal friction | Electric motors |

| Labyrinth design | Blocks dust with air paths | Mining conveyors |

| High-speed capability | Ideal for fast-rotating parts | Fans, turbines |

Both contact seals and non-contact seals are important for roller bearings. The best one depends on where and how it is used. Sealing devices help roller bearings work well in many jobs.

Bearing Seals and Materials

Rubber Seals

Rubber seals are used in many bearings. These seals use natural rubber to make a soft barrier. They stop dirt and water from getting inside the bearing. Rubber seals also keep the lubricant in, so the bearing lasts longer. Many companies use rubber seals because they are simple to put in and not expensive. But, natural rubber can get weak if it touches oil, heat, or chemicals. This means rubber seals do not work well everywhere.

Key features of rubber seals:

- Very flexible and seal well

- Easy to change because of simple shape

- Work best in places that are not too hot

Synthetic Rubber Seals

Synthetic rubber seals are better than natural rubber ones. They use materials like nitrile or fluoroelastomer. These seals can handle oil, chemicals, and heat much better. A synthetic rubber oil seal works well in cars and big machines. These bearing seals keep the lubricant inside and block bad stuff out. Synthetic rubber seals last longer and stay strong even when squeezed.

Advantages of synthetic rubber seals:

- Do not break down from oil or chemicals

- Can be used in very cold or hot places

- Give good sealing for tough jobs

Polyurethane Seals

Polyurethane seals are very strong and do not wear out fast. These seals are good for heavy-duty bearings. Polyurethane can take a lot of pressure and move many times. But, changes in temperature can change how these seals work.

- Polyurethane seals wear out faster when it gets hot. Heat makes the seal weaker and dries out the lubricant, so it wears more.

- When polyurethane gets old from heat, it gets harder. This can help stop wear, but if there are acids and heat, the seal can fail early.

- How well the seal holds lubricant depends on the heat. If it gets too hot, the seal gets soft, leaks more, and wears out faster.

- Additives in the seal can go away quickly if it is hotter than 125°C. This makes the seal less stretchy and can change its shape forever.

- If the surface is rough or there is a lot of rubbing, the seal gets hotter. This causes more wear and leaks.

Polyurethane bearing seals work best when it is not too hot and the area is clean. They seal well and last a long time if used right.

Tip: Picking the best material for oil seals helps protect bearings and keeps machines working well.

Sealing of Bearing Positions

Integrated Seals

Integrated seals are built into the bearing. They fit tightly inside the bearing. These seals block dust, dirt, and water. Integrated seals help bearings work in tough places. You do not need extra parts with these seals. This makes putting them in easier. Many engineers pick integrated seals for machines that need less fixing. These seals also keep the lubricant inside. This helps the bearing last longer.

Shielded Bearings

Shielded bearings use metal shields to protect the bearing. The shield fits in the outer ring but does not touch the inner ring. This lets the bearing spin with little friction. Shielded bearings block big pieces of dirt. They do not stop small dust or water as well as other seals. Shielded bearings work best in clean places. They are used in electric motors, fans, and office machines. Some have a snap ring to hold them in place and last longer. These bearings can handle heat up to 250°C. But they need to be checked and oiled often to work well.

- Shielded bearings block big dirt pieces.

- The gap between shield and ring means less force is needed to spin.

- They can spin fast but do not block water well.

- Shielded bearings are good when you want to keep lubricant in and have low friction.

Narrow Gap Seals

Narrow gap seals have a small space between the shield and ring. This space makes it hard for dirt to get in. These seals do not touch moving parts, so there is almost no friction. Narrow gap seals work well in fast-spinning roller bearings. They give basic protection and help keep lubricant inside. These seals are used when you need good sealing but also want low drag.

Tip: Picking the right sealing shield for each bearing helps it last longer and need less fixing.

Oil Seals and Selection

Application Factors

Oil seals are very important in many bearing jobs. They keep the lubricant inside and stop bad dirt from getting in. Engineers pick oil seals by looking at a few key things. The job type tells them what seal design, material, and size to use. Rotary shaft seals work best in machines with spinning parts. Double lip seal designs have two lips. One lip keeps the lubricant in. The other lip keeps dirt out. This makes the seal work better in tough jobs.

Key things to think about include:

- Shaft speed: Fast shafts need rotary shaft seals with low friction. This helps stop heat from building up.

- Pressure: Some jobs need seals that can handle high pressure and not leak.

- Shaft size and housing: The seal must fit tight to stop leaks and work well.

- Type of lubricant: Oil seals should not swell or break when used with different lubricants.

Note: Double lip seal designs are often used in cars and factories when extra sealing is needed.

Environment and Load

Where the seal works changes how well it works. Temperature, chemicals, dust, and water all matter. How much load and shaking the seal gets also changes how it works.

- Very hot or cold places can make seals hard or break. This makes them fail faster.

- Chemicals can break down seal materials. Fluorocarbon rubbers help seals last longer in harsh chemicals.

- Vibration or bad installation can make seals fail early.

- Fast shafts need rotary shaft seals with low friction. Heavy loads need strong seal materials.

- Dust, water, and chemicals must be checked to make sure the seal lasts a long time.

Fatigue, repeated loads, and squeezing can make seals fail. Big hits can break seals fast. As seals get older, heat makes cracks grow and the seal gets harder. Oxygen and chemicals in the air make seals age and roughen the surface. Changes in temperature change the oil film between the seal and shaft. This can cause more wear and leaks. Seals wear out faster when it is hot or the shaft spins fast. Acid and heat together make seals wear out even faster. Scratches and damage get worse over time, causing more seal loss and failure.

Tip: Picking the right oil seals for each job helps stop early failure and keeps bearings working well.

Maintenance

Taking care of oil seals helps them last longer in bearings. Checking seals often helps find early wear, leaks, or hard spots. Changing seals before they break stops bearing damage and saves time. Double lip seal and rotary shaft seals need extra care in tough places. Cleaning around the seal and using the right oil also helps the seal work better.

A simple checklist for oil seal care:

- Look at seals for cracks, hard spots, or leaks.

- Make sure the seal fits and lines up right.

- Change seals that look worn out.

- Clean the area to get rid of dust and dirt.

- Use oils that work with the seal material.

| Maintenance Task | Purpose | Frequency |

|---|---|---|

| Visual inspection | Find cracks or leaks | Monthly |

| Lubricant check | Stop dry running | Every 3 months |

| Seal replacement | Prevent sudden failure | As needed |

| Area cleaning | Lower dirt and dust | Weekly |

Regular care of oil seals helps them seal well and makes bearings last longer in all jobs.

Picking the best sealing structure for roller bearings is important. It helps the bearing work well and last longer. Sealing devices keep dirt out and hold the lubricant in. Companies like NSK and SKF have made better seals. These new seals help bearings last longer and lower friction. This is very helpful in tough jobs. Every job is different. Engineers need to choose the right seal for speed, load, and where it will be used. If you pick the right seal, the bearing will last longer and need less fixing. If you need help with sealing, contact us, TFL Bearings can give you expert advice.

FAQ

What is the main purpose of a roller bearing seal?

A roller bearing seal keeps dirt and moisture out of the bearing. It also holds lubricant inside. This helps the bearing work smoothly and last longer.

What types of materials are used for bearing seals?

Manufacturers use rubber, synthetic rubber, and polyurethane for bearing seals. Each material offers different levels of flexibility, strength, and resistance to heat or chemicals.

What is the difference between contact and non-contact seals?

Contact seals touch the moving parts and create a tight barrier. Non-contact seals use a small gap or special path to block dirt. Contact seals provide better protection, while non-contact seals allow faster rotation.

What problems can occur if a seal fails?

Seal failure can let dirt and water enter the bearing. Lubricant may leak out. This can cause faster wear, overheating, and early bearing failure.

What should engineers check during seal maintenance?

Engineers should look for cracks, leaks, or hard spots on the seal. They should also check if the seal fits well and replace it if worn. Regular cleaning helps keep the seal working.