Comparing Precision and Standard Ball Bearings

Explore if high precision bearings justify their extra cost.

| Features | Precision Ball Bearings | High Precision Ball Bearings |

|---|---|---|

| Tolerance Levels | Tighter than standard, moderate precision | Tightest tolerances, micron-level accuracy |

| Material Quality | 440C stainless steel, corrosion resistant | Premium alloys like M50, BG42, cobalt |

| Performance | Better accuracy and reduced noise | Superior speed, low vibration, high reliability |

| Service Life | Longer than standard, moderate extension | Up to 17 times longer lifespan |

| Cost | Moderate cost, balanced quality | Highest cost, premium investment |

| Application Suitability | Automotive, industrial automation | Aerospace, robotics, medical equipment |

| Vibration and Noise | Reduced compared to standard | Minimal vibration and noise |

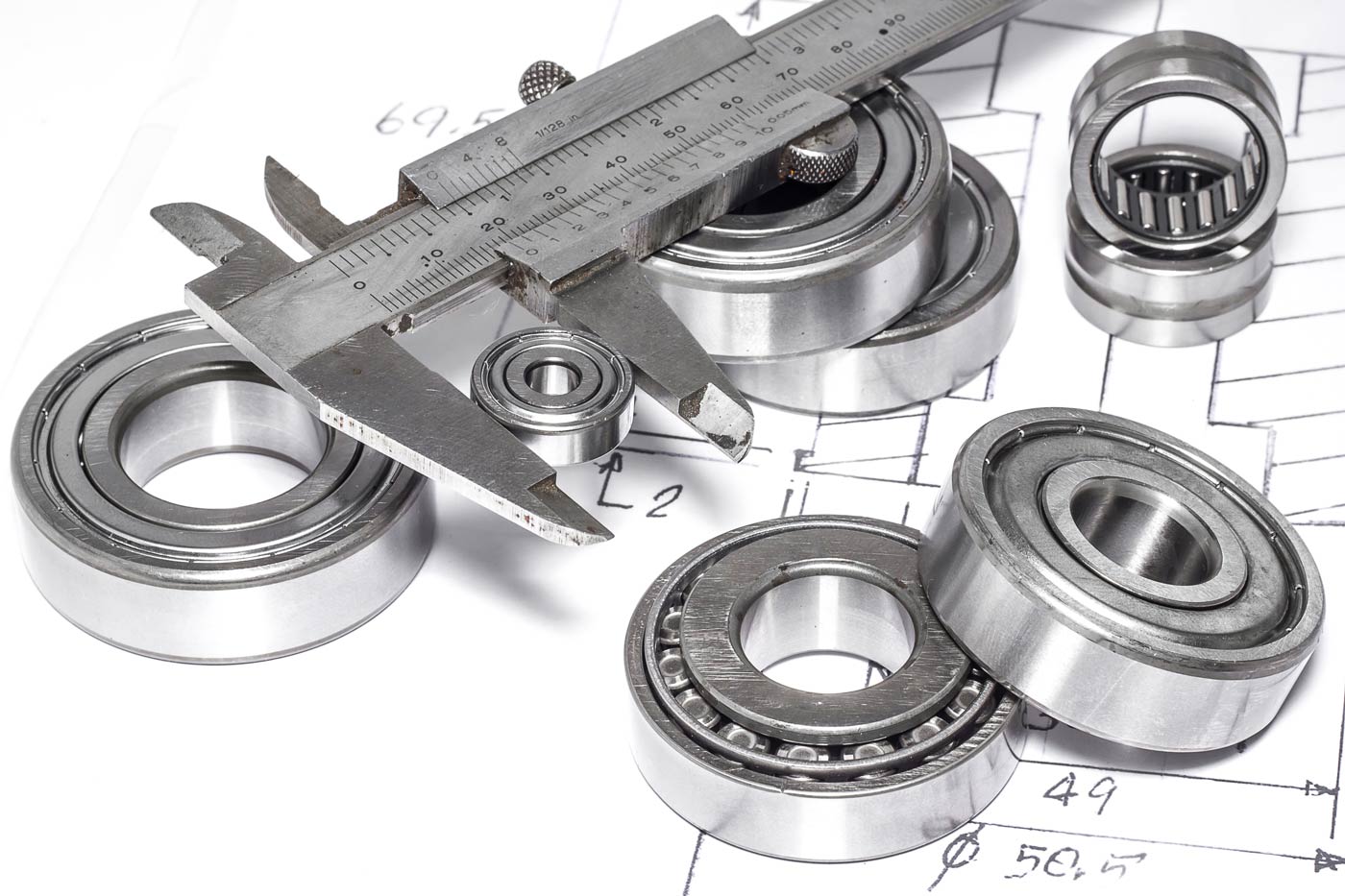

| Manufacturing Control | Advanced measurement tools used | Extensive quality control, atomic force microscopy |

An engineer faces a choice: invest more in high-precision ball bearings or select standard options. This decision can impact machine performance, cost, and reliability. High precision ball bearings reduce peak loads by up to 60% and improve stiffness by up to 78%, leading to a service life up to 17 times longer than lower grade versions.

| Performance Metric | Impact Compared to Lower Grade Versions |

|---|---|

| Peak Load Reduction | Up to 60% |

| Stiffness Improvement | Up to 78% |

| Service Life Extension | Up to 17 times longer |

Understanding these precision levels helps buyers match the right bearing to their needs.

Key Takeaways

- High precision ball bearings offer much tighter tolerances and better materials than standard bearings, leading to longer life and improved performance.

- Choosing the right bearing depends on the application’s speed, accuracy, and load needs; high precision bearings suit critical, high-speed, or sensitive machines.

- Standard ball bearings work well for general machinery with moderate demands and cost less, while precision bearings provide a middle ground.

- High precision bearings reduce vibration and noise, which helps machines run more quietly and reliably.

- Investing in high precision ball bearings can save money over time by extending service life and reducing maintenance in demanding applications.

Bearing Types

Standard Ball Bearings

Standard ball bearings serve as the foundation for most general-purpose machinery. Manufacturers produce these bearings according to international standards such as ABEC, ISO, and DIN. These standards ensure consistent tolerances and quality across different brands. Standard bearings use common materials like chrome steel and follow basic manufacturing steps: material selection, forging, machining, heat treatment, grinding, assembly, and inspection.

- Typical features include:

- Wider tolerances compared to higher-grade bearings

- Adequate performance for moderate speeds and loads

- Lower cost and broad availability

Performance differences in standard ball bearings often result from variations in cage type, ball diameter, and raceway curvature. These factors affect load capacity, friction, and durability. Standard bearings work well in applications where extreme precision is not required.

Precision Ball Bearings

Precision ball bearings offer tighter tolerances and improved reliability over standard types. These bearings usually meet ISO P5 or ABEC 5 levels. Manufacturers use advanced measurement tools like coordinate measuring machines and laser systems to ensure micron-level accuracy. They also test surface finish and hardness to optimize friction and wear resistance.

Precision ball bearings undergo rigorous quality control, including material integrity checks, dimensional accuracy, and surface finish analysis. These steps help maintain consistent performance and longer service life.

Precision bearings suit applications that demand higher speeds, better accuracy, and reduced vibration. Industries such as automotive and industrial automation often rely on these bearings for critical components.

High Precision Ball Bearings

High precision ball bearings represent the top tier in bearing technology. These bearings meet ISO P4 or ABEC 7 (or better) standards, which means they have the tightest manufacturing tolerances. Manufacturers validate their performance through advanced engineering tests, including frictional torque, temperature, and endurance testing under simulated real-world loads.

- Key characteristics:

- Superior dimensional accuracy and surface finish

- Use of premium-grade materials, sometimes including ceramics

- Enhanced reliability and performance at very high speeds

High precision ball bearings undergo extensive quality control, such as atomic force microscopy for surface analysis and fatigue life testing for long-term reliability. These bearings excel in demanding environments like aerospace, robotics, and medical equipment, where even minor deviations can affect system performance.

Precision Grades

ABEC and ISO Ratings

Engineers and buyers often compare ball bearings using ABEC and ISO ratings. These systems set the standards for dimensional accuracy and running tolerances. ABEC, short for Annular Bearing Engineering Committee, uses a scale from 1 to 9. ISO 492, the international equivalent, uses classes like 6X, 6, 5, 4, and 2. Both systems help users select the right bearing for their needs.

Higher ABEC or ISO grades mean tighter tolerances and better performance. Lower grades work well for general machinery, while higher grades suit demanding applications.

The table below compares ABEC grades and their key tolerances:

| ABEC Grade | Bore and Outer Diameter Tolerance (inches) | Radial Runout (inches) | Radial Play Range (inches) | Performance Implication |

|---|---|---|---|---|

| 1P | ±0.0003 to ±0.0004 | ~0.00040 to 0.00060 | ~0.0002 to 0.0020 | Baseline precision, meets ABMA Standard 20 |

| 3P | ±0.0002 to ±0.0003 | ~0.00020 to 0.00040 | Moderate radial play | Improved precision and lower runout than 1P |

| 5P | ±0.0002 | ~0.00015 to 0.00020 | Moderate radial play | Superior race finish and geometry, recommended for precision assemblies |

| 7P | ±0.0002 | ~0.00010 to 0.00015 | Moderate radial play | High precision, low noise, longer life potential |

| 9P | ±0.0001 to ±0.00015 | ~0.00005 to 0.00010 | Tightest radial play | Highest precision, minimal runout, best for critical applications |

Tighter tolerances reduce vibration and noise. They also extend bearing life, especially in high-speed or high-load environments.

Grade Classification

ABEC and ISO grades map directly to each other. This mapping helps users compare bearings from different regions or manufacturers. The following table shows the relationship:

| ABEC Class | ISO 492 Equivalent Class |

|---|---|

| ABEC 1 | Normal class 6X |

| ABEC 3 | Class 6 |

| ABEC 5 | Class 5 |

| ABEC 7 | Class 4 |

| ABEC 9 | Class 2 |

- ABEC classes define how much a bearing’s dimensions can vary. For example:

- A 20 mm inner diameter bearing has a 10 μm tolerance for ABEC 1.

- The same bearing has a 5 μm tolerance for ABEC 7.

- Maximum runout values also decrease with higher grades. ABEC 1 allows 10 μm, while ABEC 9 allows only 1.5 μm.

The evolution of these standards began with early rolling elements and advanced with the needs of aerospace and high-speed industries. Today, both ABEC and ISO ratings guide buyers in choosing the right balance between cost and performance.

Key Differences

Tolerances

Tolerances set the foundation for how ball bearings perform in real-world applications. Standard ball bearings have wider tolerances, which means their dimensions can vary more from one unit to another. Precision and high precision ball bearings feature much tighter tolerances. Ultra precision bearings show peak-to-peak motion errors as low as 10 to 100 nanometers. These small errors result from advanced manufacturing, careful design, and strict quality control.

Manufacturers measure tolerances using parameters like bore diameter, outer diameter, and ring parallelism. For example, ABEC-9 rings paired with ABMA Grade-3 balls create the highest precision class. Experimental tests, such as vibration analysis and high-speed camera imaging, reveal that tighter tolerances reduce motion error, vibration, and uneven loading. These tests also show that high precision ball bearings maintain their accuracy even under heavy loads and high speeds.

| Bearing Type | Typical Tolerance (μm) | Motion Error (nm) | Vibration Level | Application Suitability |

|---|---|---|---|---|

| Standard | 10-20 | 500+ | High | General machinery |

| Precision | 5-10 | 100-500 | Medium | Automation, automotive |

| High Precision | 1-5 | 10-100 | Low | Aerospace, robotics, medical |

Performance

Performance differences between bearing types become clear in demanding environments. Standard ball bearings provide reliable service for moderate speeds and loads. Precision bearings improve on this by offering better accuracy, reduced noise, and longer life. High precision ball bearings excel in applications where even the smallest error can cause problems.

Laboratory tests measure performance using benchmarks like dynamic load rating, static load rating, and rating life (L10). High precision bearings show superior results in these tests. For example, they maintain low vibration and noise levels, even at high speeds. Vibration signal analysis helps detect faults early, which is critical for industries that cannot afford downtime. High precision bearings also tolerate less misalignment and require minimum loads to prevent skidding, ensuring consistent operation.

Note: Early detection of faults is easier with high precision bearings due to their stable performance and lower vibration signatures.

Materials

Material selection plays a major role in the durability and longevity of ball bearings. Standard bearings often use 52100 chrome steel, which offers good wear and fatigue resistance. Precision bearings may use 440C stainless steel, providing corrosion resistance and reliable hardness. High precision ball bearings use advanced alloys such as M50 tool steel, BG42, or cobalt-based materials. These alloys withstand higher temperatures and offer superior fatigue life.

| Bearing Type | Common Materials | Hardness (HRC) | Max Temp (°F) | Key Properties |

|---|---|---|---|---|

| Standard | 52100 Chrome Steel | 60-64 | ~310 | Good wear, basic fatigue resistance |

| Precision | 440C Stainless Steel | 58-62 | ~325 | Corrosion resistance, higher precision |

| High Precision | M50, BG42, Cobalt Alloys | 60-65 | Up to 975 | Extreme fatigue life, thermal stability |

Precision and high precision bearings also benefit from advanced heat treatment and strict metallurgical control. These processes create a uniform grain structure and enhance hardness, directly improving service life.

Cost

Cost differences reflect the complexity and quality of each bearing type. Standard ball bearings cost less due to simpler materials and wider tolerances. Precision bearings cost more because of tighter tolerances, better materials, and advanced manufacturing. High precision ball bearings represent the highest investment, justified by their superior performance and reliability.

Several factors influence cost:

- Material choice: Advanced alloys and stainless steels increase price.

- Precision class: Tighter tolerances require more precise manufacturing, raising costs.

- Lubrication: Specialized lubricants for high speeds or temperatures add expense.

- Cage design: Metal, stainless steel, or engineered plastics affect both speed and price.

- Noise and vibration: Quieter, smoother bearings require better surface finishes and stricter quality control.

| Factor | Standard Bearings | Precision Bearings | High Precision Bearings |

|---|---|---|---|

| Material Cost | Low | Medium | High |

| Manufacturing Cost | Low | Medium | High |

| Performance Value | Basic | Enhanced | Superior |

| Typical Price Range | $ | $ | $$ |

Buyers should weigh these costs against the demands of their application. For critical systems, the extra investment in high precision ball bearings often pays off through longer service life and reduced maintenance.

High Precision Ball Bearings in Applications

When to Use High Precision

Engineers often face a choice between standard, precision, and high precision ball bearings. The right decision depends on the application’s demands. High precision ball bearings deliver the best results in environments where accuracy, speed, and reliability are critical. These bearings minimize vibration and noise, which helps sensitive equipment perform at its best.

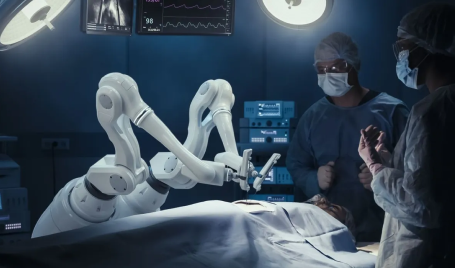

For example, high precision ball bearings work well in machines that operate at very high speeds or require exact positioning. In a medical centrifuge, these bearings cut lubrication intervals in half and reduce operational noise by about 15 dB. This improvement means less maintenance and a quieter work environment. In robotics, high precision ball bearings support servo motors and gearboxes. They extend bearing life and reduce downtime, which keeps automated systems running smoothly.

However, not every application needs this level of precision. Standard ball bearings perform well in general machinery, where loads and speeds stay moderate. Precision ball bearings offer a middle ground for applications that need better accuracy but do not face extreme conditions. Choosing the right bearing type helps control costs while meeting performance goals.

Tip: Select high precision ball bearings for applications where even small errors can cause big problems. For less demanding uses, standard or precision bearings often provide enough performance at a lower cost.

Typical Industries

Several industries rely on high precision ball bearings to achieve top performance. These sectors demand tight tolerances, long service life, and minimal maintenance.

- Aerospace: Aircraft engines, navigation systems, and control surfaces require bearings that withstand extreme conditions. Advanced bearing steels, such as powder metallurgy steels, increase hardness up to 66–67 HRC and improve fatigue life by up to six times compared to conventional steels. These improvements help aerospace systems operate reliably, even with lubricant starvation or contamination.

- Medical Equipment: Devices like MRI machines, surgical robots, and centrifuges depend on high precision ball bearings. In medical centrifuges, these bearings reduce operational noise and extend maintenance intervals, which supports patient safety and equipment uptime.

- Robotics: Industrial robots and automation systems use high precision ball bearings in joints, gearboxes, and motors. These bearings enable high-speed operation and precise movement. Longer bearing life reduces downtime and increases productivity.

- Automotive (Hybrid and Electric Vehicles): Electric motors in hybrid vehicles benefit from high precision ball bearings. These bearings increase system efficiency by 2% and prevent electrical discharge damage, which protects sensitive components.

| Industry | Application | Benefit/Result |

|---|---|---|

| Aerospace | Jet engines, controls | Hardness up to 67 HRC; fatigue life up to 6x longer |

| Medical | Centrifuges, MRI | Noise reduced by ~15 dB; longer lubrication intervals |

| Robotics | Servo motors, gearboxes | Longer life; supports high-speed, precise operation |

| Automotive | Electric motors | 2% higher efficiency; zero electrical discharge damage |

Not every industry needs high precision ball bearings. Construction equipment, agricultural machinery, and many consumer products perform well with standard or precision bearings. These applications do not require the tightest tolerances or the highest speeds. By matching the bearing grade to the application, companies can balance performance and cost.

Choosing Precision Grade

Assessing Needs

Selecting the right precision grade starts with a clear understanding of the application’s requirements. Engineers often use quantitative models to evaluate how bearing errors affect machine performance. For example, a 5-degree-of-freedom (5-DOF) quasi-static model helps measure raceway errors, such as radial and axial runouts, side sway, and waviness. This model gives a precise way to compare different bearing grades.

A key metric, the error homogenization coefficient, shows that the combined inner and outer raceway errors usually fall between 0.6 and 0.8 times the bearing runout error. For high precision bearings, like the 7014 P2, radial and axial runouts measure about 1.3 micrometers. These numbers help engineers set clear tolerance limits for each grade.

Tip: Use measurable criteria, such as runout and side sway, to compare bearing options. Outer ring raceway errors often need to be much lower than inner ring errors, especially in high-speed or high-accuracy machines.

Matching Grade to Application

Matching the precision grade to the application involves balancing performance needs with cost. The ABEC rating system defines classes from ABEC 1 to ABEC 9. Each class sets limits for bore diameter, radial runout, and ring width. Most general machines use ABEC 1 or 3 bearings. High-speed spindles or robotics often require ABEC 7 or 9.

- Key risk factors to consider:

- Tighter tolerances reduce noise, vibration, and imbalance.

- Higher grades extend bearing life at high speeds.

- Over-specifying increases costs without added benefit.

- Standardized measurement methods help control quality and reduce risk.

Advances in manufacturing now make high-precision bearings more available. However, choosing a higher grade than needed can raise costs without improving performance. Engineers should match the grade to the real demands of the application, using both quantitative data and risk assessment.

Comparison Table

Selecting the right ball bearing type depends on several key factors. Engineers often compare load ratings, performance coefficients, tolerances, life expectancy, and cost. Each bearing type offers unique strengths for specific applications.

A clear comparison helps buyers match the right bearing to their needs and budget.

Below is a comprehensive table that highlights the main differences among common ball bearing types:

| Bearing Type | Load Ratings (C) | Performance Coefficients (X, Y) | Shaft Fit Tolerances | Housing Fit Tolerances | Life Expectancy (hours) | Cost Implications |

|---|---|---|---|---|---|---|

| Single-Row Radial Contact | Varies by size and angle | X, Y for load calculations | K5, J6 recommended | J6, H7 recommended | Application dependent | Lower cost, basic precision |

| Angular Contact (Single/Double Row) | Adjusted for mounting | Power factors for tandem setups | Similar to radial | Similar to radial | Adjusted for load sharing | Higher cost, more complex |

| Double-Row Radial Contact | Combined single row values | Adjusted for load distribution | Consistent with single row | Standard fits | Higher due to load sharing | Increased cost, complex design |

| Self-Aligning Ball Bearings | Lower for same size | Special coefficients (cotangent/tangent) | Adapted for self-aligning | Adjusted for design | Affected by misalignment | Specialized, higher cost |

- Load Ratings (C): These values show how much force a bearing can handle. Angular contact and double-row bearings often support higher loads due to their design.

- Performance Coefficients (X, Y): Engineers use these numbers to calculate how bearings respond to different forces. Angular contact bearings use special power factors for tandem mounting.

- Tolerances: Shaft and housing fits like K5, J6, and H7 ensure proper alignment and reduce vibration. Tighter tolerances mean higher precision.

- Life Expectancy: Bearings with better load distribution or self-aligning features often last longer, especially in demanding environments.

- Cost Implications: More complex designs and tighter tolerances increase manufacturing costs. High precision and specialized bearings usually cost more but deliver superior performance.

Choosing the right bearing type ensures reliable operation and maximizes value for each application.

High precision ball bearings prove valuable in industries that demand accuracy, speed, and long service life. Standard and precision bearings meet most general needs at a lower cost. Buyers should compare application requirements, budget, and expected performance. If uncertainty remains, TFL Bearings offers expert guidance. We help customers select the right bearing for every project. Contact us for tailored solutions.

FAQ

Can I tell the precision grade of a bearing from its model number?

In most cases, yes. Many bearings include the precision grade in the model suffix—for example, P5, P4 (ISO) or ABEC-5, ABEC-7 (ANSI/ABMA). Standard bearings usually don’t show a precision suffix and default to the basic grade, such as P0 or ABEC 1. If it’s not shown, it’s best to check the datasheet or ask your supplier to be sure.

When should someone choose high precision ball bearings over standard ones?

Engineers select high precision ball bearings for machines that need high speed, accuracy, or low noise. Standard ball bearings work well in general machinery with moderate loads and speeds.

Do high precision ball bearings last longer than standard ones?

Yes. High precision ball bearings often last up to 17 times longer than standard types. Their advanced materials and strict manufacturing processes increase service life.

Are high precision ball bearings always worth the extra cost?

Not always. High precision ball bearings provide value in critical applications. Standard or precision bearings meet most needs at a lower price. Users should match bearing grade to application requirements.

Can high precision ball bearings reduce machine vibration?

High precision ball bearings reduce vibration and noise. Their tight tolerances and smooth surfaces help machines run quietly and efficiently.