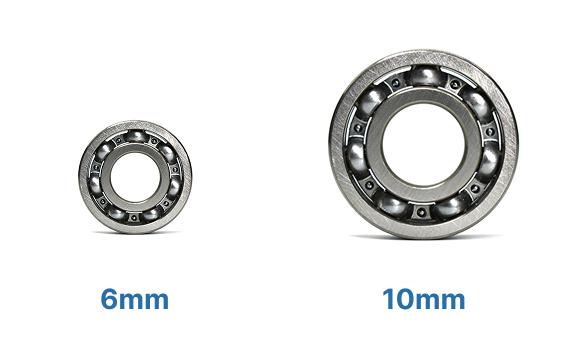

Key Differences Between 6mm and 10mm Ball Bearings

Explore load, speed, and applications of 6mm vs 10mm bearings.

| Features | 6mm Ball Bearings | 10mm Ball Bearings |

|---|---|---|

| Inner Diameter | 6 mm inner diameter for compact shafts | 10 mm inner diameter for larger shafts |

| Outer Diameter | 18 mm outer diameter, smaller footprint | Larger outer diameter, supports bigger loads |

| Load Capacity | Supports up to 1000 kg working load | Handles higher loads, more stability |

| Maximum Speed | Up to 8 m/s, ideal for high speed | Also up to 8 m/s, smooth operation |

| Material | Chrome Steel SAE-52100, durable | Stainless steel, chrome steel, ceramic options |

| Lubrication | Re-lubrication via annular groove | Sealed with synthetic rubber, self-lubricating |

| Operating Temperature | Standard temperature range | -40°C to +120°C wide range |

| Applications | Compact devices, robotics, medical tools | Heavy machinery, industrial equipment, turbines |

| Space Requirements | Fits tight spaces, lightweight designs | Requires more installation space |

| Durability | Good for light to moderate loads | Better for heavy-duty, long service life |

You want to know which size performs better for your needs. 6mm ball bearings fit compact spaces and move at high speeds, while 10mm bearings handle higher loads. The latest figures show that both sizes support a maximum load of 2023 lbf (9000 N) and reach speeds up to 8 m/s (315 in/sec).

| Specification | Value |

|---|---|

| Maximum Load | 2023 lbf (9000 N) |

| Maximum Speed | 8 m/s (315 in/sec) |

| Available Bushing Sizes | 6 mm, 10 mm |

If you need small, fast-moving parts, 6mm ball bearings work well. For heavier loads or more stability, 10mm bearings offer a better solution.

Key Takeaways

- 6mm ball bearings fit small spaces and support high speeds, making them ideal for compact, fast-moving devices.

- 10mm ball bearings handle heavier loads and offer greater stability, perfect for heavy-duty and industrial applications.

- Both sizes can reach speeds up to 8 m/s, but material choice like ceramic balls can improve speed and reduce heat.

- Choose bearing size based on your load, speed, and space needs; use size charts and consider environment and lubrication.

- Proper selection and installation prevent failures; always match bearing size and material to your specific application.

6mm Ball Bearings

Features

You will find that 6mm ball bearings stand out in the world of miniature ball bearings. These bearings use a single-piece race type construction and have a width 6mm, making them compact and efficient. The inner diameter measures 6 mm, while the outer diameter is 18 mm. Chrome Steel SAE-52100 gives these miniature bearings strength and durability. You can re-lubricate them through an annular groove with two interconnecting holes at 180 degrees. This design helps reduce friction and keeps the bearings running smoothly. The deep groove ball bearings design ensures reliable performance in both radial and axial loads.

| Feature | Description |

|---|---|

| Inner Diameter | 6 mm |

| Outer Diameter | 18 mm |

| Width | 6 mm |

| Material | Chrome Steel SAE-52100 |

| Construction Type | Single piece race type construction |

| Contact Design | Metal-to-metal contact between components |

| Lubrication | Re-lubrication possible via annular groove with two interconnecting holes at 180 degrees |

| Static Load Rating | 2,271 lbf |

| Dynamic Load Rating | 944 lbf |

| Lubrication Type | Light oil |

Load Capacity

You can rely on 6mm ball bearings for impressive load handling in miniature applications. These bearings support a maximum working load of 1000 kg and a breaking load of 3000 kg.

| Parameter | Value |

|---|---|

| Ball Bearing Diameter | 6mm |

| Maximum Working Load | 1000kg |

| Breaking Load | 3000kg |

Speed

Miniature ball bearings like the 6mm size excel at high speeds. You can achieve up to 8 m/s (315 in/sec) with these bearings. The deep groove ball bearings design helps minimize friction, so you get smooth, fast rotation. This makes 606 ball bearings ideal for applications where speed and efficiency matter most.

Applications

You will see 6mm ball bearings used in many miniature and precision engineering fields. Common applications include railway engineering, bridge building, hydraulic steel structures, and wind turbines. These miniature ball bearings also perform well in high shock and alternating load environments. When you need low friction and reliable movement in a compact space, 6900 ball bearings deliver strong results.

Tip: Size differences between 5 mm and 6 mm miniature ball bearings affect velocity and penetration depth, especially in softer materials like Fibreboard Underlay. However, in harder materials such as MDF, the impact of size on performance is limited. You can trust 6mm ball bearings to resist deformation and maintain consistent performance, even under tough conditions.

10mm Ball Bearings

Features

You will notice that 10mm ball bearings offer several advanced features that set them apart from smaller options. These miniature ball bearings use seals made from oil and wear-resistant synthetic rubber, reinforced with steel. This design protects the bearings from dirt and grease, which helps extend their lifespan and maintain lubrication. You can use them in temperatures ranging from -40°C to +120°C, so they work well in many environments. The deep groove ball bearings have deep raceway grooves, which means you get high load capacity and reliable performance. Manufacturers use high-quality materials like stainless steel, chrome steel, and ceramic to ensure durability. Advanced manufacturing techniques, such as automatic grinding and ultrasonic testing, help create precise and consistent miniature ball bearings. Strict quality control, certified by international standards, guarantees that you receive reliable products every time.

- Sealed design keeps out contaminants

- Wide operating temperature range

- High-quality materials for durability

- Advanced manufacturing for precision

- Deep groove ball bearings for high load capacity

Load Capacity

When you compare 10mm ball bearings to 6mm options, you see a clear difference in load handling. The larger size allows these miniature ball bearings to accept both radial and axial loads, making them more versatile. You can rely on them for heavy-duty tasks where stability and strength matter most. The deep groove design supports higher loads without increasing friction, so you get smooth operation even under stress. These bearings are available in standard and C3 clearance options, letting you choose the best fit for your application.

Speed

You can expect 10mm ball bearings to perform well at high speeds, similar to 6mm bearings. The sealed design and high-quality materials reduce friction, which means you get quiet and smooth operation. Performance testing shows that these miniature ball bearings operate efficiently, even at maximum speeds. The 6800 2RS model, for example, offers low friction and self-lubrication, making it ideal for demanding uses.

Applications

You will find 10mm miniature ball bearings in many industries. They work well in heavy machinery, electric motors, and precision instruments. Their ability to handle both high loads and high speeds makes them suitable for applications where reliability and durability are essential. If you need miniature ball bearings for a challenging environment, the 10mm size provides a strong balance of performance and longevity. You can also use 6900 ball bearings in similar settings, especially when you need low friction and long service life.

Tip: Choose 10mm miniature ball bearings when your application demands higher load capacity, durability, and stable performance in tough conditions.

Miniature Ball Bearings Comparison

Load

You need to consider load capacity when choosing between 6mm and 10mm miniature ball bearings. The size of the bearing directly affects how much weight it can support. Here is a quick comparison:

| Bearing Size | Maximum Working Load | Breaking Load | Typical Use |

|---|---|---|---|

| 6mm | 1000 kg | 3000 kg | Light to moderate loads in compact spaces |

| 10mm | Higher than 6mm | Higher than 6mm | Heavy-duty loads and greater stability |

6mm ball bearings work best in applications where space is tight and the load is not extreme. You get reliable performance for small devices and precision tools. 10mm miniature ball bearings handle heavier loads. You should use them when your application demands more strength and stability. Both sizes offer strong performance, but the 10mm option gives you extra support for demanding tasks.

Speed

Speed is another key factor in the application of miniature ball bearings. Both 6mm and 10mm bearings can reach high speeds, up to 8 m/s (315 in/sec). However, the material of the rolling elements can make a big difference. When you use ceramic balls instead of steel, you see up to 82% less centrifugal load. This means the bearings run cooler and can spin faster without overheating. Ceramic balls also make the bearing stiffer and less sensitive to temperature changes. If you choose bearings with ceramic rolling elements, you get higher speed and better performance, especially in high-speed miniature applications.

Material choice also affects speed stability and vibration. Bearings made from carbon-filled PTFE reach stable speeds after a short running-in period. PEEK bearings have lower vibration but less stable speed. You should match the material to your needs for the best results. For most users, both 6mm and 10mm miniature ball bearings offer excellent speed, but the right material can give you an edge in demanding environments.

Use Cases

You will find that the application of miniature ball bearings depends on both size and load requirements. Here is a side-by-side look at common uses:

- 6mm Ball Bearings:

- Small electric motors

- Precision instruments

- Robotics and automation

- Medical devices

- Compact gearboxes

- 10mm Ball Bearings:

- Heavy machinery

- Industrial equipment

- Electric motors with higher loads

- Wind turbines

- Railway engineering

You should use 6mm ball bearings when you need a compact solution for light loads and high speeds. These bearings fit well in tight spaces and delicate devices. For larger machines or when you need more durability, 10mm miniature ball bearings are the better choice. They provide extra strength and longer service life in tough conditions.

Tip: Always match the bearing size and material to your specific application of miniature ball bearings. This ensures you get the best performance and reliability for your project.

Pros and Cons

6mm Ball Bearings

You will notice several advantages when you choose 6mm ball bearings. Their small size makes them perfect for tight spaces and lightweight designs. You can use them in devices where every millimeter counts. These bearings also allow for high-speed rotation, which helps in applications that need quick movement.

Pros:

- Fit easily into compact spaces

- Support high-speed operation

- Reduce overall weight of your device

- Work well in precision instruments and robotics

Cons:

- Handle lower loads compared to larger bearings

- May not provide as much stability in heavy-duty applications

Tip: You should pick 6mm ball bearings if your project needs speed and space-saving features.

10mm Ball Bearings

You will find that 10mm ball bearings offer a different set of strengths. Their larger size lets you handle heavier loads and gives your equipment more stability. You can rely on them for machines that face tough working conditions.

Pros:

- Carry higher loads with ease

- Offer greater stability for your machinery

- Perform well in heavy-duty and industrial settings

- Operate reliably across a wide temperature range

Cons:

- Require more installation space

- Add extra weight to your design

Note: You should select 10mm ball bearings when your application demands strength and durability over compactness.

Choosing the Right Size

Selection Tips

Selecting the right ball bearing size for your application can make a big difference in performance and reliability. You want to match the bearing to your needs for load, speed, and space. Here are practical steps to help you choose between 6mm and 10mm miniature bearings:

- Define Your Requirements

Start by listing your operational needs. Think about the type of load (radial, axial, or combined), the speed you need, the temperature range, and the environment. For example, if you work in a dusty or wet area, you may need sealed bearings. - Check the Shaft Size and Space

Use a miniature bearing size chart to compare the inner and outer diameters of 6mm and 10mm bearings. Make sure the bearing fits your shaft and the available space. If you have limited room, 6mm bearings often fit better. - Calculate Load and Speed

Use catalog data and a miniature bearing size chart to check the maximum load and speed ratings. For heavy loads, 10mm bearings usually offer more support. For high-speed needs in small devices, 6mm bearings often perform best. - Estimate Bearing Life

Use industry formulas to estimate how long the bearing will last under your load and speed. The formula L = LR (C/Fr)^3.33 helps you predict bearing life, where L is life, LR is rated life, C is rated capacity, and Fr is applied force. - Select Lubrication and Clearance

Choose the right lubrication for your speed and temperature. Grease works well for most uses, but oil may be better for high-speed or high-temperature jobs. Check the clearance rating (like C3) on the miniature bearing size chart to match your needs for expansion or precision. - Consider Material and Environment

Look at the material options in the miniature bearing size chart. Chrome steel suits most uses, but stainless steel or ceramic may work better in harsh or high-speed environments. Always match the bearing material to your working conditions.

Tip: Always compare your options using a miniature bearing size chart. This chart helps you see the differences in load, speed, and fit between 6mm and 10mm miniature bearings.

Common Mistakes

Many users make similar mistakes when choosing ball bearings. Knowing these can help you avoid costly errors and keep your equipment running smoothly. Here is a table showing the most common mistakes and their impact:

| Common Mistake | Description | % of Premature Failures |

|---|---|---|

| Inadequate Bearing Selection | Picking the wrong size or type without checking speed and preload needs. | 10% |

| Improper Mounting | Installing bearings incorrectly, causing misalignment or overheating. | 5% |

| Indirect Failures | Running bearings in bad conditions (overloading, overspeeding, poor handling). | 4% |

You can also run into other issues, such as:

- Letting dirt or grit get into the bearing, which causes wear.

- Using the wrong fit, which leads to heat and early failure.

- Misaligning the shaft, which increases temperature and damages the separator.

- Not using enough lubrication, which causes overheating.

- Allowing water or chemicals to cause corrosion.

- Storing bearings poorly, which leads to rust before use.

Note: Many failures happen because users skip checking the miniature bearing size chart or ignore the fit and environment. Always double-check your selection and installation steps.

When you compare 6mm and 10mm miniature bearings, remember that bigger is not always better. You need to balance load, speed, and space. For precision motion and reducing friction, the right size and material matter most. Use the miniature bearing size chart as your guide, and always consider your specific application.

TFL Bearings Recommendation

Why Choose Us

When you compare ball bearing suppliers, you want a partner who understands your needs. At TFL Bearings, you get more than just products. You receive expert advice, reliable service, and a wide selection of high-quality bearings. Our team helps you choose between 6mm and 10mm ball bearings based on your specific application, load, and speed requirements.

You can trust our experience. Over the past 15 years, customers worldwide have shifted their preference to TFL Bearings. Many now choose us over major international brands. This trust comes from our dedication to research, development, and customer satisfaction.

You benefit from our global sourcing and strict quality control. We supply only ISO-compliant bearings from top global brands. These bearings use advanced engineering and materials, so you get high performance in demanding industrial applications. Our range covers all major types, including:

- Radial and deep groove ball bearings for low friction and high speed

- Thrust ball bearings for reliable axial load support

- Self-aligning ball bearings that handle shaft misalignment

- Thin section ball bearings for space-saving designs

- Custom solutions tailored to your unique needs

You also enjoy fast delivery and competitive pricing. Our efficient supply chain ensures you get the right bearing when you need it. We offer full-service support, from selection to after-sales care.

If you want bearings that combine quality, durability, and expert support, TFL Bearings is your best choice. You can contact us for personalized recommendations and technical guidance. We help you find the perfect fit, whether you need 6mm or 10mm ball bearings for your project.

Choose TFL Bearings for your next engineering challenge. You get quality, integrity, and service every step of the way.

You now see the key differences between 6mm and 10mm ball bearings. Choose 6mm bearings for compact, high-speed projects. Pick 10mm bearings for heavier loads and more stability. To make the best choice:

- Check your load and speed needs.

- Review space and shaft size.

- Monitor bearing quality using control charts for size consistency.

Market trends and technology changes can also guide your decision. For expert help, reach out to TFL Bearings today.

FAQ

What is the main difference between 6mm and 10mm ball bearings?

You will notice that 6mm ball bearings fit compact spaces and support high speeds. 10mm ball bearings handle heavier loads and offer more stability. Choose based on your project’s size and strength needs.

Which ball bearing size lasts longer in heavy-duty applications?

You get longer service life from 10mm ball bearings in heavy-duty uses. Their larger size and stronger construction help them resist wear and damage better than 6mm bearings.

Can I use 6mm and 10mm ball bearings interchangeably?

You should not swap these sizes without checking your shaft and housing dimensions. 6mm bearings fit smaller shafts and spaces. 10mm bearings require more room and support higher loads.

Which size is better for high-speed machinery?

Both sizes reach high speeds, but 6mm ball bearings often perform better in small, fast-moving devices. For large machines that need both speed and strength, 10mm bearings work well.

How do I choose the right material for my ball bearings?

Tip: You should match the material to your environment. Chrome steel works for most uses. Stainless steel resists corrosion. Ceramic balls give you higher speed and less heat. Always check your application’s needs before choosing.