Introduction

Just think about the fan in your room, the engine in your car, or even the power tool in your shed. Bearings help them move quickly so they can get things done. Bearings cut down on friction so that things move smoothly. TFL Bearings is a reliable Chinese company that makes high-quality ball bearings for motors. Let’s talk about what kinds of ball bearings there are and how to pick the best ones for your machine.

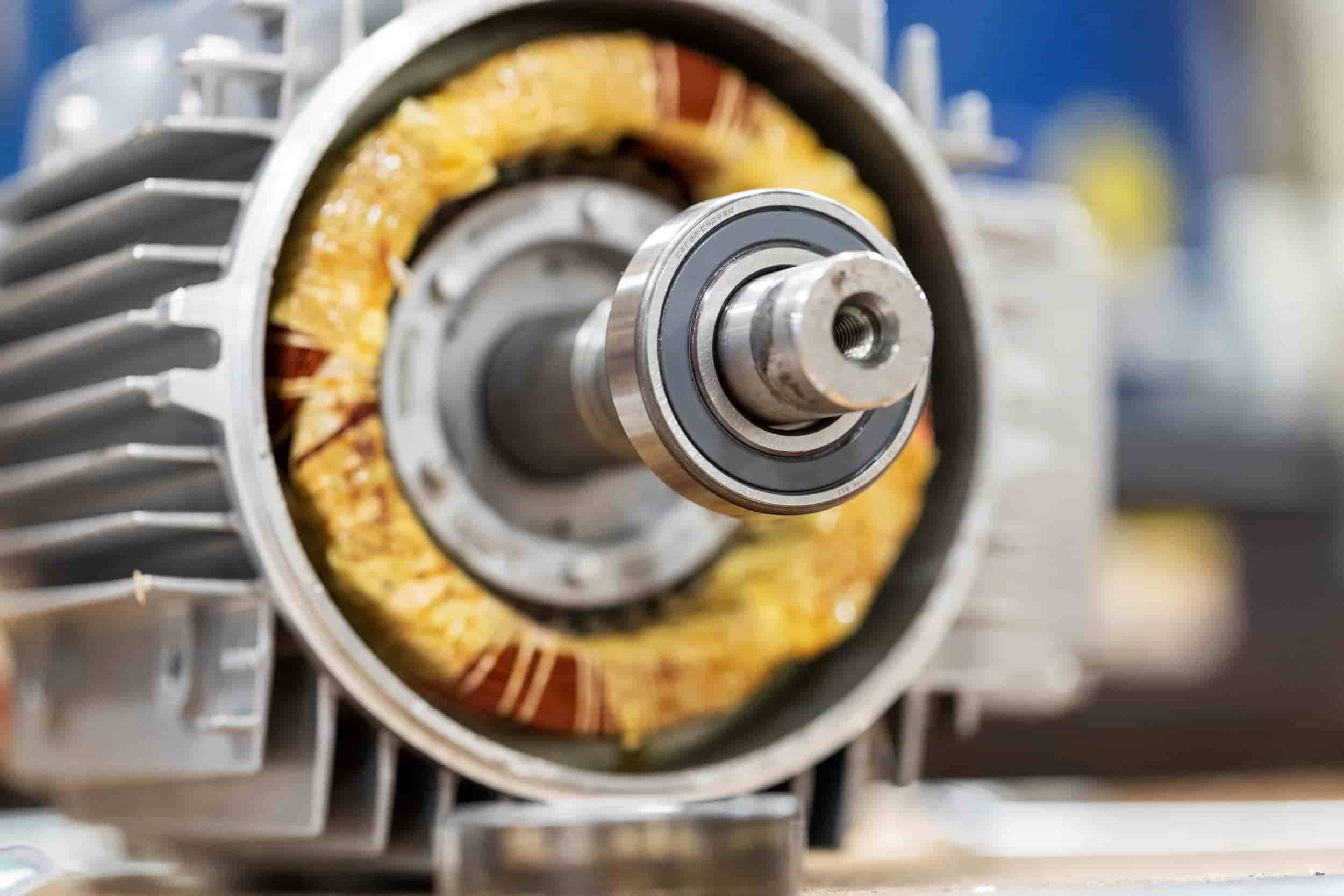

What Are Electric Motor Ball Bearings

Small metal balls called ball bearings help things move around without getting stuck. They make sure that the moving parts in electric motors don’t rub against each other too much and break. A ball bearing motor isn’t a special kind of motor, but rather a regular electric motor that uses electric motor ball bearings inside. These bearings are made up of small metal balls that roll between two smooth surfaces. This rolling motion helps reduce friction, which means things can spin much easier and with less effort.

Key Functions of Ball Bearings in Motors

- Reduce friction – Keeps the motor running smoothly and prevents overheating.

- Support loads – Handles both radial (side) and axial (push/pull) forces.

- Improve efficiency – Helps save energy by reducing resistance.

- Extend motor life – Protects moving parts from damage.

Types of Ball Bearings for Motors

There are different types of ball bearings used in motors. The right type depends on the motor’s speed, load, and working conditions.

1. Deep Groove Ball Bearings

Deep groove ball bearings are the most common type used in motors. They can take pressure from different directions without losing efficiency. They are widely used in electric motors, fans, and pumps. Deep groove ball bearings are often used in pumps, fans, and electric motors because they are simple and last a long time.

2. Angular Contact Ball Bearings

Built for motors handling a mix of radial and axial stresses, angular contact ball bearings are designed for high speed spinning. Their contact angle lets them control more loads in one direction unlike deep groove ball bearings. Angular contact ball bearings are used in a lot of different areas, such as machine tools, industrial equipment, mining equipment, oil and gas equipment, ship equipment, and more. They can provide stable and reliable support in places where things spin quickly and are loaded with weight.

3. Self-Aligning Ball Bearings

Designed to solve the shaft misalignment problem in motors, self-aligning ball bearings. Regular bearings can easily wear out a motor or generate excessive friction if the shaft of the motor moves significantly or is not quite straight during running. Inner rings of self-aligning ball bearings rotate slightly within the outer ring, enabling their automatic adjustment to these misalignments. This extends the lifetime of the bearing and the motor itself as well as lessens stress on the former.

4. Ceramic Ball Bearings

Ceramic ball bearings are made from ceramic materials instead of traditional steel, making them a great choice for high-speed and high-temperature applications. These bearings reduce friction and call for less lubrication since ceramic is lighter than metal, therefore optimizing motor efficiency. Perfect for motors running at high speeds or under harsh conditions, they also endure heat better than steel bearings. Ceramic ball bearings find regular use in high-performance electric motors, racing engines, and aerospace applications where smooth operation and longevity are paramount.

Why High-Speed Motors Need Quality Ball Bearings

Friction Makes Things Hot

Friction is that annoying rubbing that happens when things move. Think about rubbing your hands together really fast – they get warm, right? The same thing happens inside a motor. When a motor spins super fast, the parts inside rub against each other. This rubbing makes heat. Regular ball bearing deep groove bearings can get too hot and stop working the way they should. They might even get damaged.

Regular Bearings Can Wiggle

If you’ve ever seen a wobbly wheel on a toy, you know it doesn’t work very well. The same idea applies to motors. If a motor is spinning super fast, even a little bit of wiggle in the electric motor ball bearings can cause trouble. It can make the motor sound noisy, shake, or even break down completely.

Fast Motors Wear Out Bearings Quickly

Imagine riding your bike really, really fast all the time. The tires would wear out faster than if you rode slowly. The same thing happens with motors. The faster a motor goes, the more wear and tear there is on the ball bearing deep groove bearings. Regular bearings might wear out too quickly in a motor that spins super fast.

Tips for Keeping Motor Ball Bearings Working Well

Cleaning and Lubricating Bearings

Dirt and grime are a bearing’s worst enemy. Use lubricants meant for motors and gently clean bearings with a lint-free cloth. TFL Bearings sells oil kits to guard against wear and tear.

Signs Your Bearings Need Replacement

Look for grinding noises or feel for vibrations; they indicate possible bearings failing. Another red light are overheated motors. Early replacement bearings helps to prevent expensive motor damage.

Avoiding Common Mistakes

Never overload motors more than their capacity and avoid using the wrong oil. For example, even if light oils might not be enough, too thick grease traps heat.

Conclusion

Ball bearings might seem small, but they’re the backbone of any motor. Choosing the right type—like ball bearing deep groove for everyday use or high-speed ball bearings for fast machines—keeps your equipment running smoothly. At TFL Bearings, we’ve spent years perfecting our designs to meet global standards.

Ready to Upgrade Your Motors? Don’t settle for noisy or unreliable bearings. Shop TFL Bearings today for affordable, long-lasting options trusted by engineers everywhere. [Click here to browse our catalog] or [contact our team] for help picking the perfect bearings for your needs.

Common Questions About Ball Bearings for Motors

In an electric motor, can I run any ball bearing?

No. Bearing rated for their particular load, speed, and climate are what motors need. Using the incorrect kind can cause early breakdown.

Ball bearings in a motor last how long?

It relies on both motor running speed and maintenance quality. Under appropriate maintenance, they can last for years.

Should my motor bearings need replacement, how can I find out?

You should inspect your bearings if you feel additional vibrations, hear grinding or squeaking.

Are ball bearings something I could change in a motor personally?

Indeed, if you have the correct instruments. For highly precise motors, though, it is advisable to have a specialist handle it.

Should motor bearings fail, what results?

Should bearings fail, the motor can overheat, slow down, or stop running entirely. Regular maintenance helps prevent this.