Introduciton

Yep, we’re talking about ball bearings! If you’ve ever looked into buying ball bearings, you’ve probably noticed there are a ton of different sizes out there—3mm, 4mm, 6mm, 10mm, even big industrial ones. It can get confusing fast.

But don’t worry. We’re going to break it down in a way that’s super easy to understand. This article will help you understand ball bearing sizes, so you can pick the best one for your needs without a headache.

What Are Ball Bearing Sizes and Dimensions?

Understanding Metric Ball Bearings’ Diameter and Width

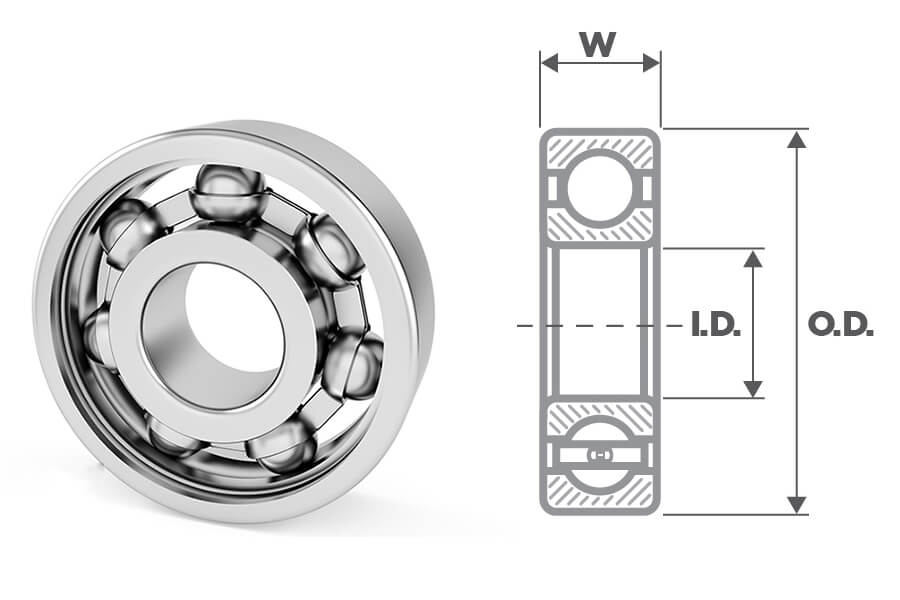

When people talk about the size of a ball bearing, they are usually talking about three main measurements. Think of it like measuring a can – you’d measure how wide the opening is, how wide the whole can is, and how tall it is.

Most of the time, these measurements are given in millimeters (mm). So, when you look at ball bearing dimensions, you’ll often see them listed like “ID x OD x Width”.

For example, a bearing that’s 25x52x15 means:

25mm inside hole (inner diameter)

52mm outside (outer diameter)

15mm thick (width)

What is the Inner Diameter (ID)?

This is probably the most important size for many people. The inner diameter is the size of the hole right in the middle of the bearing. This is where you usually slide a rod or a shaft through. It’s like the size of the circle on the inside edge.

What is the Outer Diameter (OD)?

Next is the outer diameter. This is the measurement across the whole outside of the bearing, from one edge to the other, going through the center. This size tells you how big the bearing is on the outside.

What is the Width (B or W)?

The third main measurement is the width (sometimes called the thickness). This is how “fat” or deep the bearing is from one side to the other.

How Inch Ball Bearings Show Their Size

When you’re looking at ball bearings that use inches instead of millimeters, their size is shown a little differently than the metric ones. Here are the main ways you’ll see their sizes listed:

Using Series Codes (Like R Series)

This is a common way, especially for smaller inch bearings. They often have a letter before the numbers. The most well-known group of inch ball bearings is the R series. You’ll see codes like R8, R16, R3, and so on.

For R series bearings with a bore size (the inner hole) less than 1/2 inch, the number after the ‘R’ often tells you the inner diameter in how many “sixteenths of an inch” it is.

For example, an R8 bearing usually has a 1/2 inch inner diameter (because 8/16 of an inch is the same as 1/2 inch). An R4 bearing is usually 1/4 inch inside.

But remember, this simple rule doesn’t work for all R series or other types of inch bearings, especially bigger ones. You might also see other series names, like FR for bearings with a flange (a small rim around the edge), such as FR8. There can be other older or special inch series names too.

Listing the Size Numbers Directly

Sometimes, especially for bearings that aren’t in a standard series or when showing all the details, the inner diameter (ID), outer diameter (OD), and width are just written out using inch measurements. These inches are often shown as decimal numbers or sometimes as fractions.

For example, seeing 0.250″ x 0.625″ x 0.196″ means the bearing has an inner hole of 0.250 inches, an outside of 0.625 inches, and is 0.196 inches wide.

(Just so you know, 0.250 inches is the same as 1/4 inch, and 0.625 inches is the same as 5/8 inch). You might also see the sizes written using fractions, like 1/4″ x 5/8″ x 3/16″, which is very close to the decimal example before it.

Can I Swap Metric and Inch Bearings?

Now, a question people sometimes have is: can you just use a metric bearing if you need an inch size that’s pretty close, or vice versa?

Generally, no, you really can’t swap them out like that.

Ball bearings need to fit into the parts of your machine or equipment very precisely. These parts are designed specifically to fit bearings made to either metric measurement standards or inch measurement standards.

Even if the numbers seem close when you convert them, the exact sizes and the way the bearings are manufactured are different. Trying to fit a metric bearing into a spot made for an inch one, or the other way around, won’t give you that needed exact fit. This can cause things to not work correctly, wear out too fast, or even break.

So, you need to make sure you use the right bearing that matches the standard (metric or inch) the parts were made for.

Ball Bearing Size Charts

Miniature Ball Bearings: : 3mm to 10mm

Ball bearings with an inner diameter under 10mm are usually called miniature ball bearings. These include popular sizes like 3mm, 4mm, 6mm, 8mm, and 10mm. You’ll find them in all kinds of small devices—like electric tools, drones, RC toys, cameras, and even medical tools.

- 3mm and 4mm bearings are great for small precision gadgets.

- 6mm bearings work well in stronger tools or motors.

- 8mm and 10mm bearings are often used in compact electronics and small appliances.

For example, the MR85 bearing (with a 5mm inner diameter, 8mm outer diameter, and 2.5mm width) is a popular micro bearing used in RC motors and small robots.

These small bearings don’t just save space—they also spin fast, stay quiet, and don’t need much oil. Perfect when you need something light, smooth, and compact.

Large and Industrial Ball Bearings Explained

When to Use Large Ball Bearings

Large ball bearings are made for heavy-duty jobs—like cars, wind turbines, factory machines, and big tools. They can handle more weight and keep running smoothly, even under stress.

You might hear people call them things like:

- Giant ball bearings

- Industrial large bearings

- Big ball bearings

These bearings aren’t just bigger—they’re also stronger. If you’re working with heavy loads or high-speed spinning parts, this is what you need.

Industrial Large and Metric Ball Bearings

Many of these big bearings follow metric sizing (like millimeters), which helps with global standardization. You’ll often find them in:

- Construction equipment

- Mining tools

- Heavy-duty electric motors

- Large HVAC and conveyor systems

For example, the 61820 bearing (100x125x13mm) is a big, open-style metric bearing that’s often used in large machines. It’s wide and tough, but still spins with less friction.

Other Ball Bearing Size Parameters

| Parameter | Description |

| Chamfer Dimension | A small angled edge on the bearing corner to prevent scratches during installation. |

| Contact Angle | The angle between the ball and the raceway, affects how much axial load it can handle. |

| Groove Depth | How deep the raceway is in deep groove ball bearings; deeper means more load capacity. |

| Ball Diameter | Size of the internal balls, determines load capacity and speed. |

| Number of Balls | Total number of balls inside the bearing, affects stability and load. |

| Cage Type | Determines how balls are spaced; comes in metal, nylon, or other materials. |

| Internal Clearance | The “looseness” between inner and outer rings (e.g., C2, CN, C3). |

| Seal/Shield Type | Types include open, Z (shielded), or RS (rubber seal), depending on dust protection. |

| Tolerance Class | Precision level, like P0 (standard), P6, or P5; higher means better accuracy. |

If you’re curious about any of the ball bearing size parameters listed above, feel free to check out more articles on our website. We’ve got simple guides that explain each term with real examples to help you choose the right bearing for your needs.

Get the Right Bearings from TFL Bearings

Awesome job learning about ball bearing sizes and dimensions. At TFL Bearings, we are experts in making all kinds of ball bearings right here in China and sending them all over the world.

We have tons of different sizes, including all the common ones we talked about and many more. We are here to help you find the perfect bearing for your specific needs.

Ready to get the exact ball bearings you need? Don’t guess on size! Come check out our huge selection at TFL Bearings or send us a message. We make it easy to find and buy the right bearings so your project can run smoothly!