Home/All products/Brands/FAQ

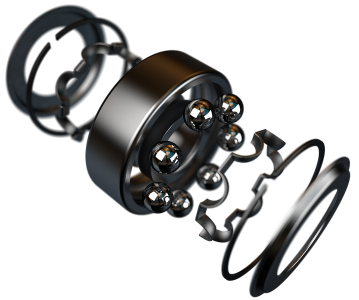

What is the basic function of a bearing? Why is it essential for machine operation?

- Basic Function: The main job of a bearing is to reduce friction between moving parts and to support loads. Think of it as making movement easier and smoother, like wheels on a skateboard. It allows parts like shafts or wheels to rotate or slide with less effort and wear.

- Why Essential: Machines rely on bearings because:

- Efficiency: Less friction means less energy wasted, so machines run more efficiently.

- Reduced Wear: Bearings prevent parts from grinding directly against each other, making them last much longer.

- Load Support: They carry the weight (load) of rotating parts, keeping them in the correct position.

- Smooth Operation: They ensure parts move smoothly and accurately, which is crucial for performance.

- Without bearings, most machines would quickly wear out, overheat, or seize up completely.

Besides type, what other general factors should be considered when selecting bearings? (e.g., lifespan, noise, cost)

- Lifespan Required: How long does it need to last?

- Speed: Maximum and typical operating RPM.

- Load Capacity: Can it handle the specific forces?

- Noise: Is quiet operation needed?

- Stiffness: How much does it deflect under load?

- Environment: Temperature, dirt, moisture exposure?

- Maintenance: Sealed-for-life or needs re-lubrication?

- Availability & Cost: Can you get it easily and does it fit the budget?

How is bearing life defined? What are the key factors affecting bearing life?

- Bearing Life Definition: Bearing life is usually defined statistically as “L10 life”. This means the number of hours or revolutions that 90% of a group of identical bearings, operating under the same conditions, are expected to complete or exceed before showing the first signs of metal fatigue (spalling/flaking). It’s a measure of reliability, not a guarantee that every single bearing will last exactly that long.

- Key Factors Affecting Life: Many things influence how long a bearing actually lasts:

- Load: Higher loads significantly reduce life. Even brief overloads can cause damage.

- Speed: Running too fast can increase temperature and wear.

- Lubrication: Insufficient, excessive, incorrect type, or contaminated lubricant is a major cause of failure.

- Contamination: Dirt, debris, or moisture entering the bearing damages rolling surfaces.

- Installation/Mounting: Incorrect fits (too tight/loose), misalignment, or damage during installation shorten life.

- Operating Temperature: Extreme heat or cold can degrade lubricant and affect bearing materials.

- Vibration: Excessive vibration can damage bearings.

How to determine if a bearing needs replacement? What inspection methods are there?

- Noise: Grinding, clicking, or screeching sounds.

- Vibration: Increased roughness or shaking.

- Heat: Running noticeably hotter than usual.

- Poor Performance: Machine runs rough or loses accuracy.

- Visible Damage: Cracks, rust, or leaks (if visible).

What are the storage requirements for bearings? How to prevent rust or damage during storage?

Proper storage is crucial to ensure bearings are in perfect condition when installed:

- Keep in Original Packaging: Don’t open the wrapping until immediately before installation. The packaging protects against dirt and moisture.

- Clean, Dry Environment: Store bearings indoors in a clean, dry area with stable temperature (ideally around room temperature) and low humidity (below 60% is often recommended). Avoid condensation.

- Avoid Vibration: Don’t store bearings near machines that cause vibrations, as this can damage the raceways over time (false brinelling).

- Store Flat: Larger bearings should generally be stored flat on their sides, not stacked too high, to prevent deformation. Avoid storing them directly on concrete floors.

- Handle Carefully: Don’t drop bearings or subject them to impacts.

- Shelf Life: Bearings (especially those with grease) have a shelf life. Follow the “first-in, first-out” principle. Check manufacturer recommendations if storing for very long periods (grease can degrade over several years).

How do high/low temperatures or corrosive environments affect bearings? How to select bearings resistant to these conditions?

Yes, the thickness of the steel will affect the heating time. Only bearings of the same size and thickness can be heated together. Many outsourced heat treatment plants will heat different thicknesses of steel in the same heated together. Many outsourced heat treatment plants will heat different thicknesses of steel in the sameess of the steel will affect the heating time. Only bearings of the same size and thickness can be heated together. Many outsourced heat treatment plants will heat different thicknesses of steel in the same heated together. Many outsourced heat treatment plants will heat different thicknesses of steel in the same …

What information do bearing model codes usually represent? Is there a general interpretation guide?

How can I quickly find the bearing I need on sdtflbearing.com? What search or filtering functions are available?

What are your policies regarding ordering, payment, shipping, and returns/exchanges?

If I encounter technical difficulties in selection or use, what support can I get from sdtflbearing.com?

CAN’T FIND WHAT YOU NEED?

Please provide your question.

We’ll find you with the best support options.